Apps and APIs

To control and use HEBI hardware we provide Applications and APIs that run on a wide variety of operating systems.

Applications

Applications include GUIs that provide a user-friendly interface for things like viewing feedback, configuring modules, or getting feedback from other devices.

| App | Description | OS Support |

|---|---|---|

A GUI for doing basic tasks on modules like visualizing feedback in real-time, manually sending commands, setting name/family, configuring controller, tuning gains, and updating firmware. |

Windows (Win64) |

|

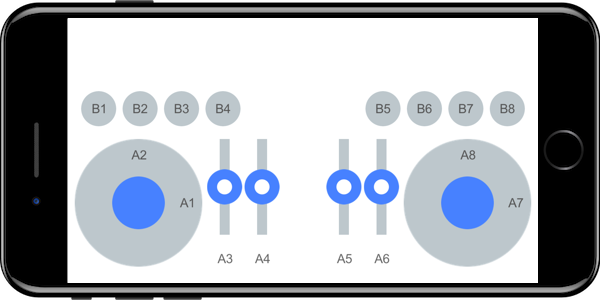

A mobile app that provides basic user input on a touch screen and provides easy access to a number of internal sensors from the mobile device. The app provides on-screen buttons and sliders for sending digital and analog inputs, mirroring the physical capabilities of the HEBI I/O Board, that can be read in the various APIs, including a layout that acts as a joystick. |

iOS |

|

A wrapper around joysticks/gamepads that exposes inputs to the HEBI APIs as an IO-type device, and can therefore be used in place of the Mobile IO application for control inputs. |

Windows (Win64) |

APIs

APIs allow you to write programs in different languages that interface with HEBI hardware. All of these apps and APIs can be found in the Downloads section, and an a walkthrough of the core API concepts can be found here.

| API | Description | OS Support |

|---|---|---|

The Matlab API is a released API that runs in the standard Matlab working environment with no additional add-ons or toolboxes. |

Windows (Win64) |

|

The Python API is a released API that is provided as source code wrapping a C library to guarantee maximum portability across operating systems. It is available at https://pypi.python.org/pypi/hebi-py. |

Windows (Win32 / Win64) |

|

The C++ API is a released API that is provided as source code wrapping a C library to guarantee maximum portability across compilers, platforms, and operating systems. |

Windows (Win32 / Win64) |

|

We provide multiple ways of interfacing with HEBI components using both ROS 1 and ROS 2, although the ROS 1 API is legacy and no longer actively maintained. |

Linux (i686 / x86-64 / armhf / aarch64) |

|

C |

A low-level API that is generally not intended for direct use. |

Windows (Win32 / Win64) |

File Formats

HEBI uses a number of file formats to store robot configuration information in a way that is easy to version and access across the different Apps and APIs. These include kinematic information, joint-level gains, motor driver settings, and high-level robot configuration files.

| File Format | Description | Supports |

|---|---|---|

A config file format designed to store configuration information about a full system in a human-readable cross-API format. |

Scope |

|

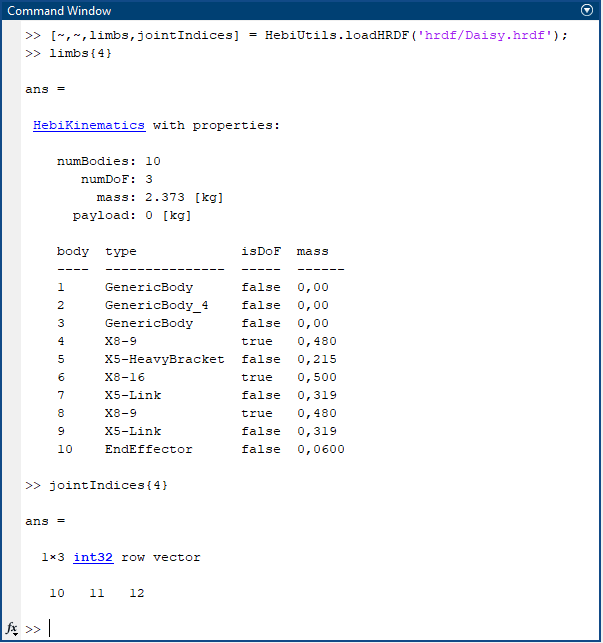

A format that allows saving and loading of the kinematics and dynamics information about a robot configuration. |

Scope |

|

A format for saving and loading all the control parameters for the onboard controllers for individual modules, as well as groups of modules. |

Scope |

|

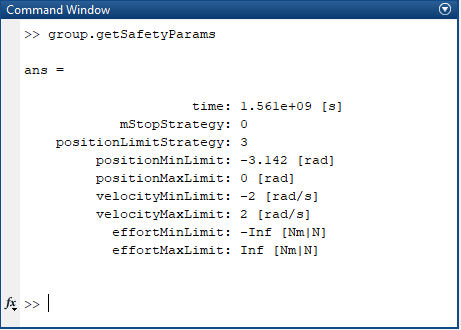

A format for saving and loading all the setting safety parameters (e.g. position/velocity/torque limits, m-stop strategies) for individual modules, as well as groups of modules. |

Scope |

|

A format for saving and loading all the configuration parameters for HEBI’s configurable motor driver. |

Scope |

Scope

Scope is a cross-platform graphical user interface (GUI) tool that provides configuration, monitoring, and testing capabilities for HEBI actuators and modules.

We recommend using Scope at all stages of your development, particularly its plotting and logging capabilities.

Before writing a new program Scope is useful to make sure that all devices are connected properly and that the system as a whole is working as expected. While developing and debugging a new application Scope is extremely useful for viewing the feedback and tuning gains on the live system.

Getting Started

-

Download the latest Release for your OS.

-

Make sure all modules are powered on and connected to your local network.

-

Start the application by double-clicking.

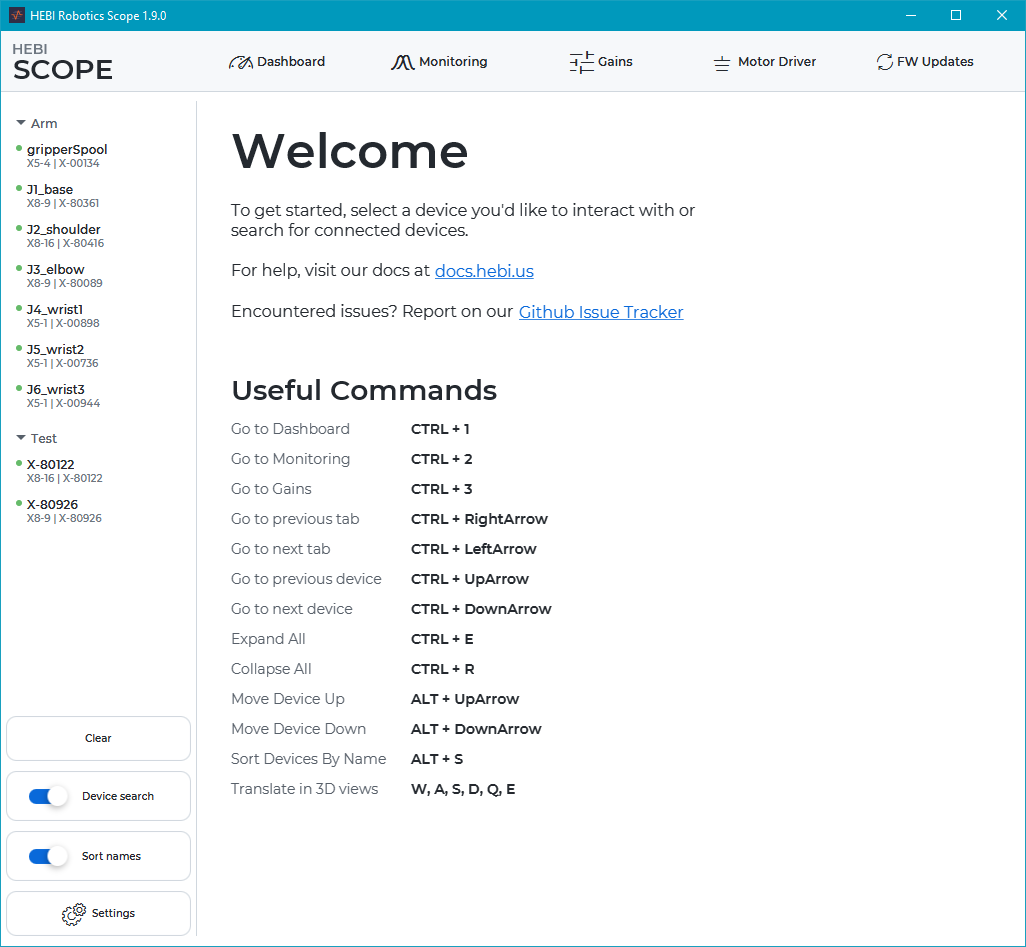

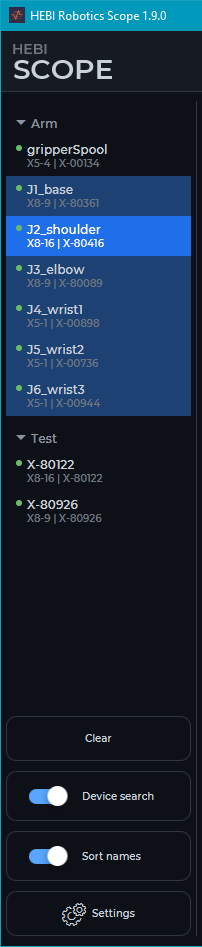

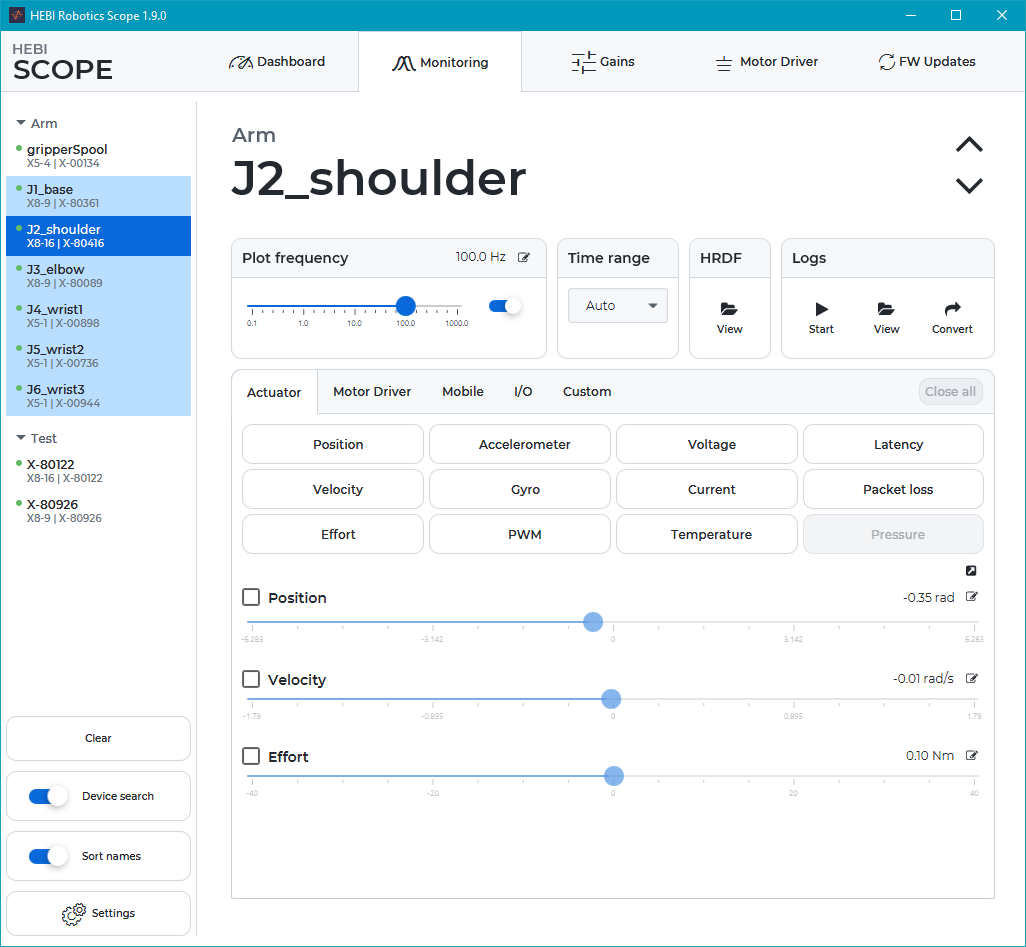

Scope starts with a screen that looks similar to the screenshot above. The items in the screenshot are, respectively:

-

A Welcome screen that provides links to the main documentation page as well as an overview of keyboard shortcuts

-

The Device Panel on the left that shows all devices visible on the network.

-

Tabs for the various panels:

-

Dashboard shows general device information such as hardware revisions and Ethernet settings, as well as various states.

-

Monitoring provides plots of device feedback as well as manual inputs for position, velocity, and effort.

-

Gains sets control strategies, gains, and safety limits.

-

Motor Driver sets parameters for motor driver devices.

-

Firmware Updates allows to safely update device firmware.

-

-

Configuration options

-

Device Search enables or disables the device lookup. Disabling will reduce network traffic, but it will keep the individual GUI elements from being updated.

-

Sort Names enables or disables the alphabetical sorting of device names. The device order can be manually modified using

ALT + UPorALT + Down -

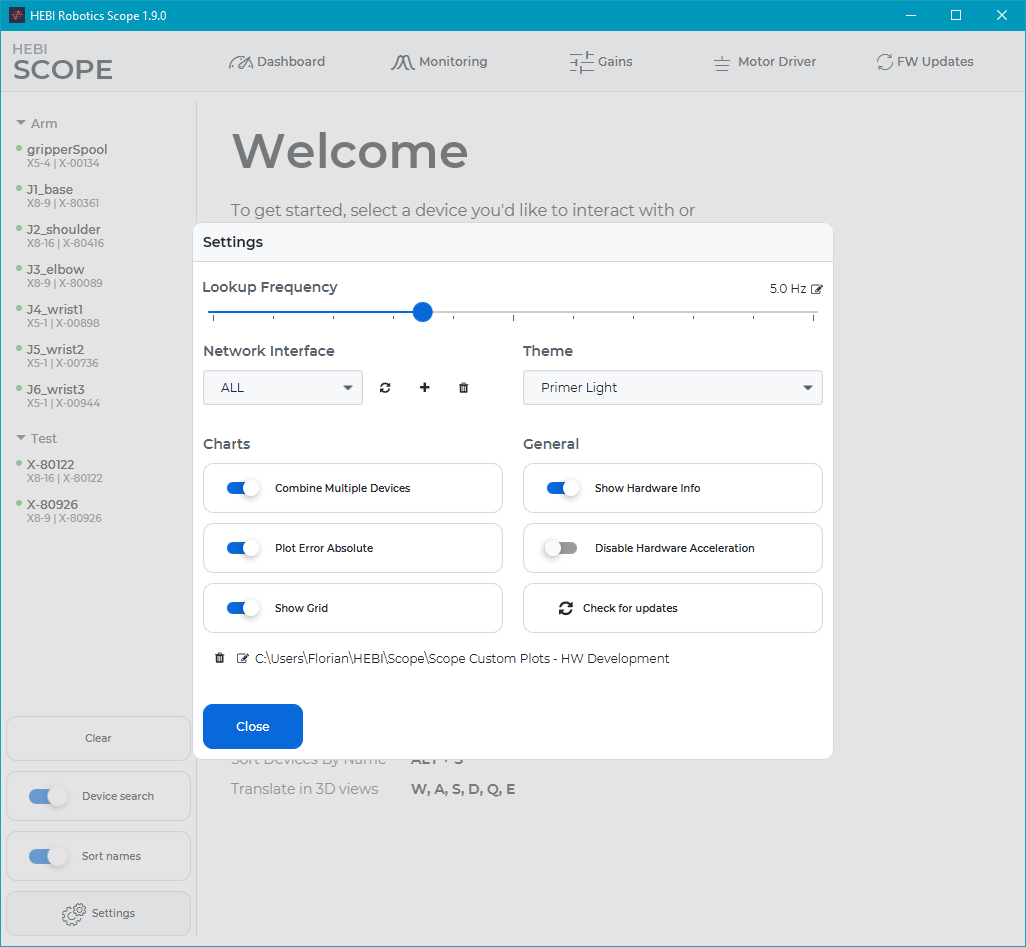

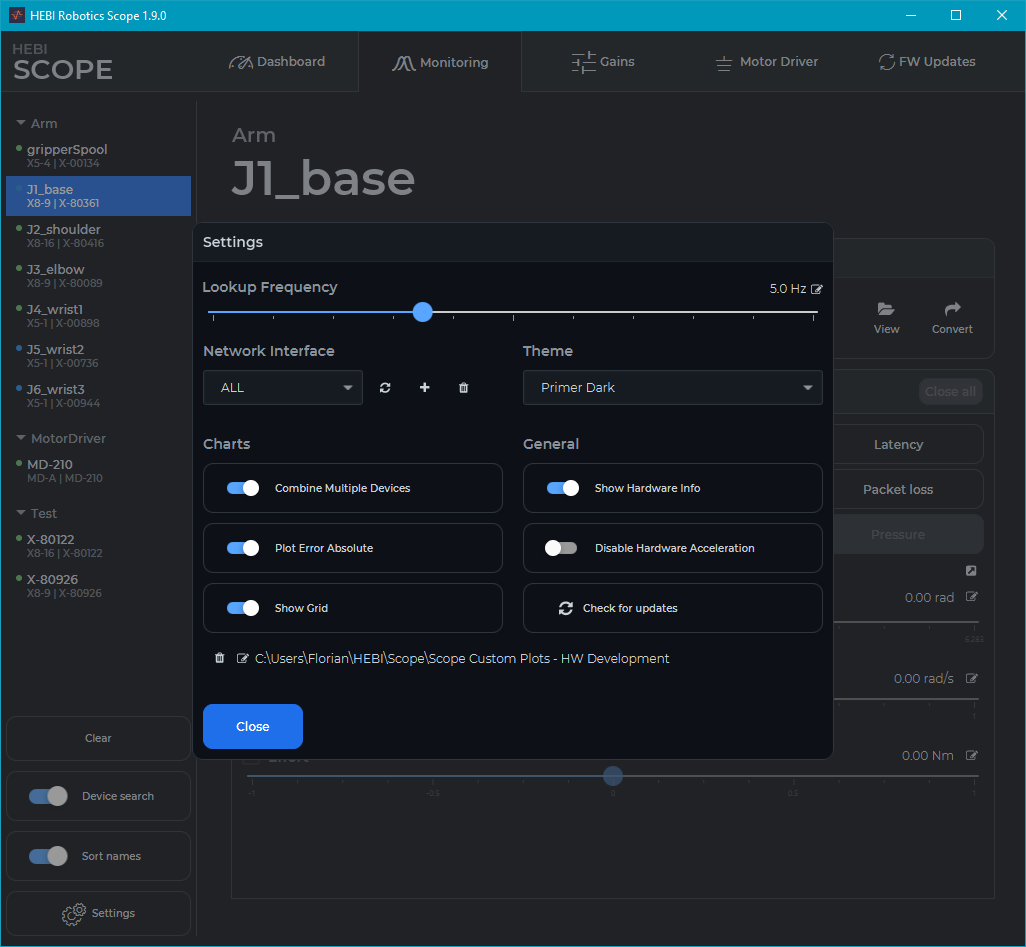

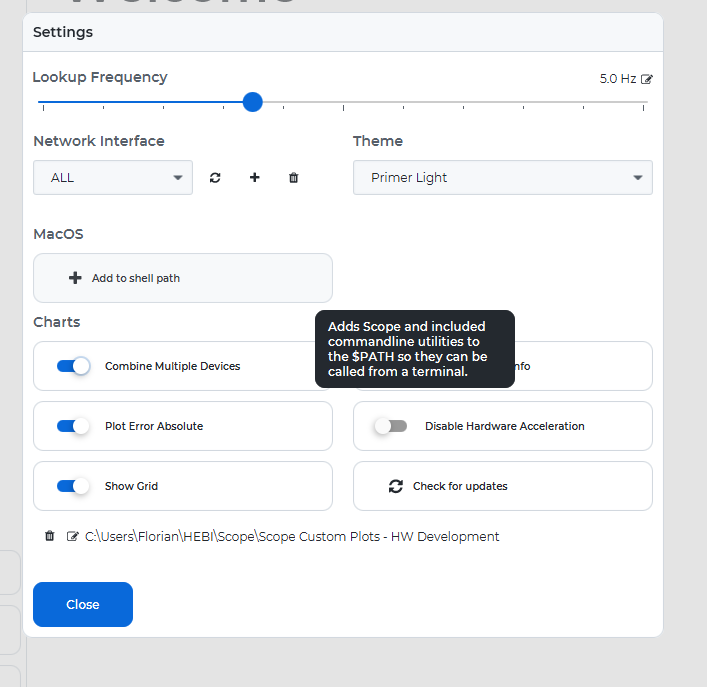

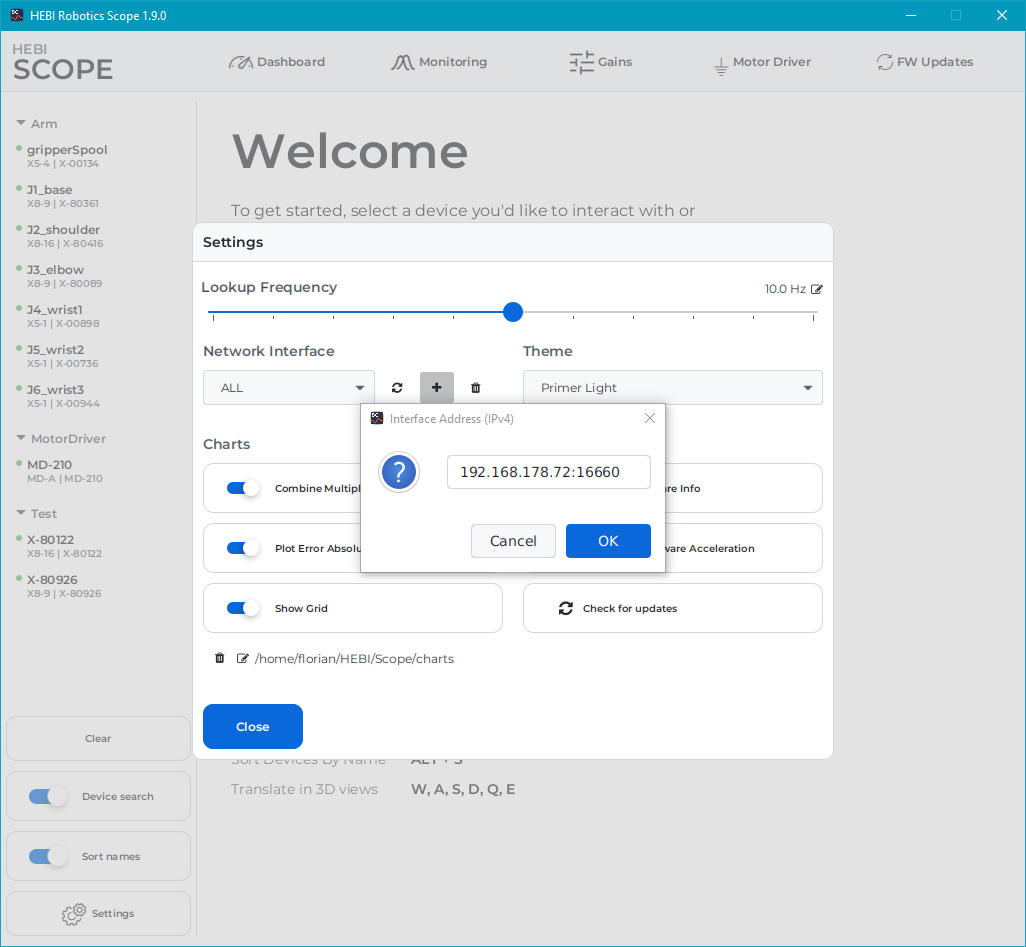

Settings: brings up a menu with additional settings as shown in the screenshot below. Please refer to the tooltips for detailed information.

-

In Settings you can also choose between different coloring themes and perform manual update checks.

Device Panel

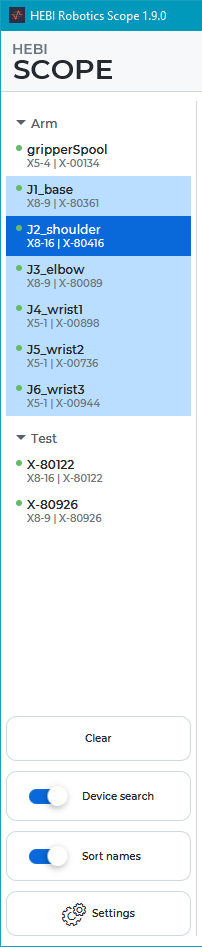

The Device Panel shows all devices that are visible, or were recently visible, on the network.

The main action in the panel is to select one or more devices for interaction. When multi-selecting, the darker highlighting represents the device that is currently in focus and corresponds to the feedback shown in the information tabs.

The colored dots indicate the current status:

-

Blue: device is reachable and in Bootloader mode

-

Green: device is reachable and in Application mode

-

Grey: device has not been reachable for at least 5 seconds

You can remove all devices that are not currently on the network (ones represented by a grey dot) by clicking the Clear button.

If you have devices that you think are currently on the network, but are not shown in the device panel, try the following:

-

Confirm that the Device Search toggle is enabled.

-

Update the network interfaces by clicking the Refresh button in the Settings Dialog.

-

Confirm that each device has successfully booted and connected to the network up by looking at the LED Status Codes

-

Confirm that the computer that Scope is running on is on the same network as the devices, and that the computer’s networks settings are properly configured.

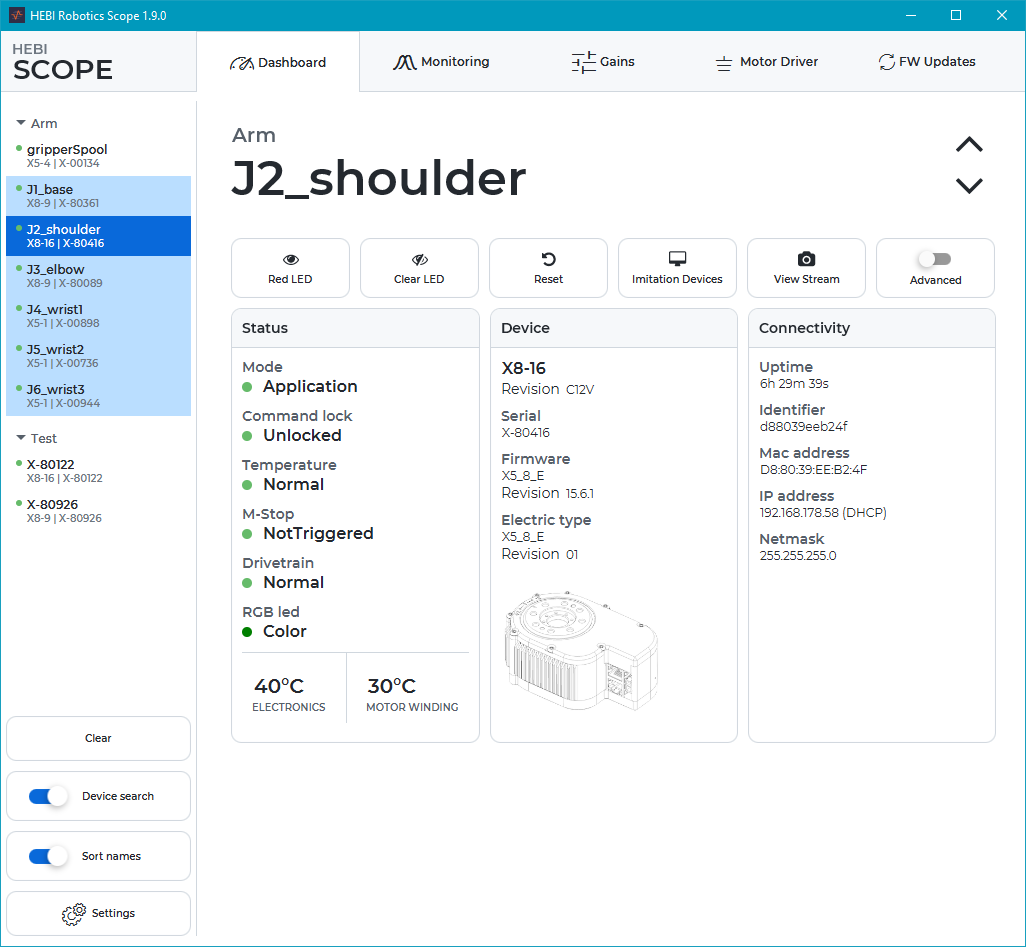

Dashboard Tab

The Dashboard Tab shows general device information such as hardware revisions and Ethernet settings.

-

The Status section provides details of the various states that the device is in.

-

The Device section shows the details of the mechanical electrical components of the module as well as information about the currently running firmware. The mechanical details are permanent and will never change.

-

The Connectivity section shows the MAC Address of the module, which is permanent, as well as network parameters that will depend on the details of your network configuration.

-

The Advanced slider shows additional parameters that provide access to hardware features such as modifying internal encoder offsets. This should be used with caution. Refer to the tooltips for more information.

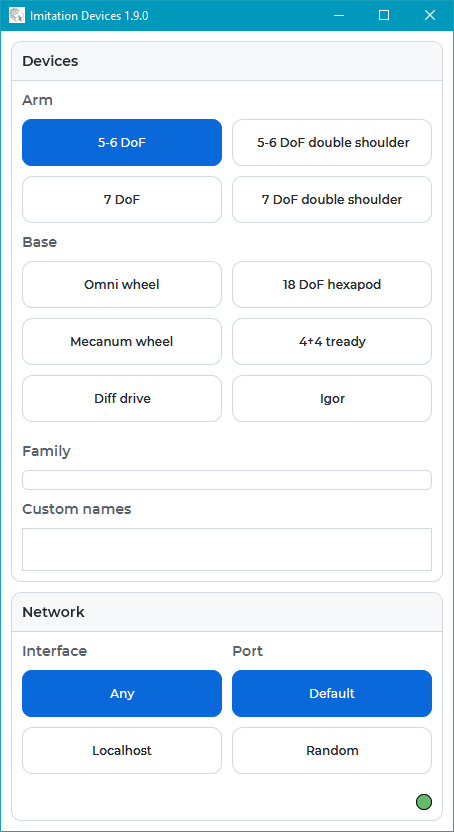

The Imitation Devices button launches a set of networked imitation modules that can be used to test and debug code before running it on real hardware. Imitation devices return commands as feedback and do not include physics feedback such as IMU data.

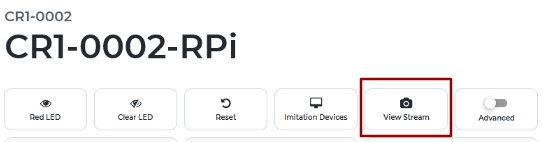

View Stream displays the contents of a video stream file created by hebi-video. It provides a way to view arbitrary video sources with relatively low overhead and latency.

Monitoring Tab

The Monitoring Tab provides a way to plot device feedback, work with log files, and provide basic inputs for position, velocity, and effort.

The Monitoring Tab has the following main features:

-

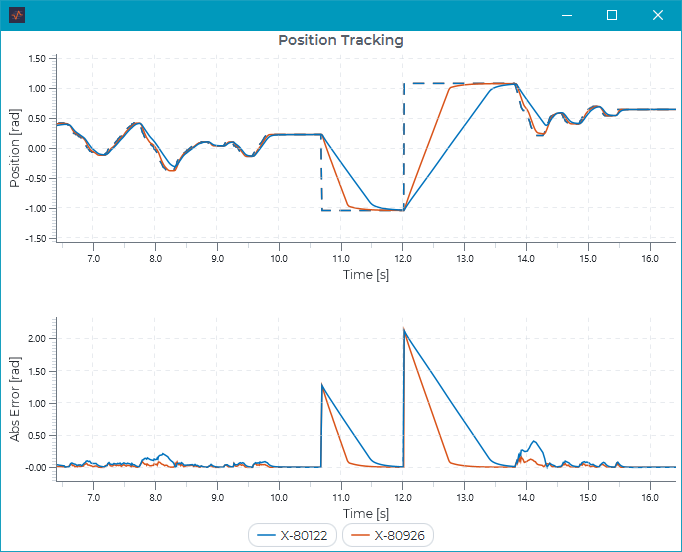

Plotting buttons open live charts of the selected devices at the update frequency specified by the frequency slider. The time-axis is specified by the time range, and the y-axis of charts is scaled automatically. Clicking on the legend toggles the visibility of individual traces.

-

Command sliders enable sending of basic commands to the selected modules. Commands can be any combination of position, velocity, and effort. The initial commands after enabling the slider will be set to the device’s current state. Specific values can be specified using the target buttons.

-

View HRDF creates a 3D visualization of the HRDF contents and maps the contained joints to zero or more selected devices.

-

Start Log creates a .hebilog file of the feedback of all selected modules at specified feedback frequency. Only one log can be active at a time.

-

View Log visualizes the data inside a .hebilog file.

-

Convert Log converts the contents of a .hebilog file to non-proprietary formats such as CSV or MAT.

For example, to check the position feedback from a module, select an appropriate device on the left panel, and then click Position plot to view the module’s reported position. Commands can be generated by enabling the Position checkbox and moving the corresponding slider. Alternatively, you can command an exact value using the corresponding target button.

The dashed line represents the commanded position, and the solid line the feedback position.

|

Commands are sent with a command lifetime disabled. This means that commands sent from Scope to a module will stay active until another command is sent, and new commands from any API will immediately override the last command from Scope. If you close Scope, previous commands sent from Scope will still remain active on a module. Unchecking the command slider will clear a given commmand. The slider inputs will not work if someone is actively commanding an actuator with command lifetime enabled. |

Scope is a completely standalone process with a separate network connection that is independent from any user code, and can be run in parallel with any other application on the same computer or local network. When debugging your applications we highly recommend making use of Scope’s plotting capabilities in order to get live feedback on the behavior of an algorithm. For example, math errors often show up as large spikes or full drop-outs in the commanded line of position, velocity or effort.

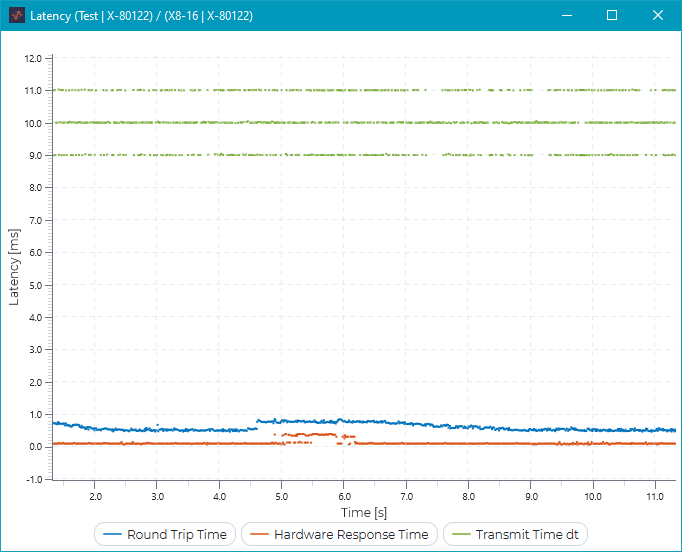

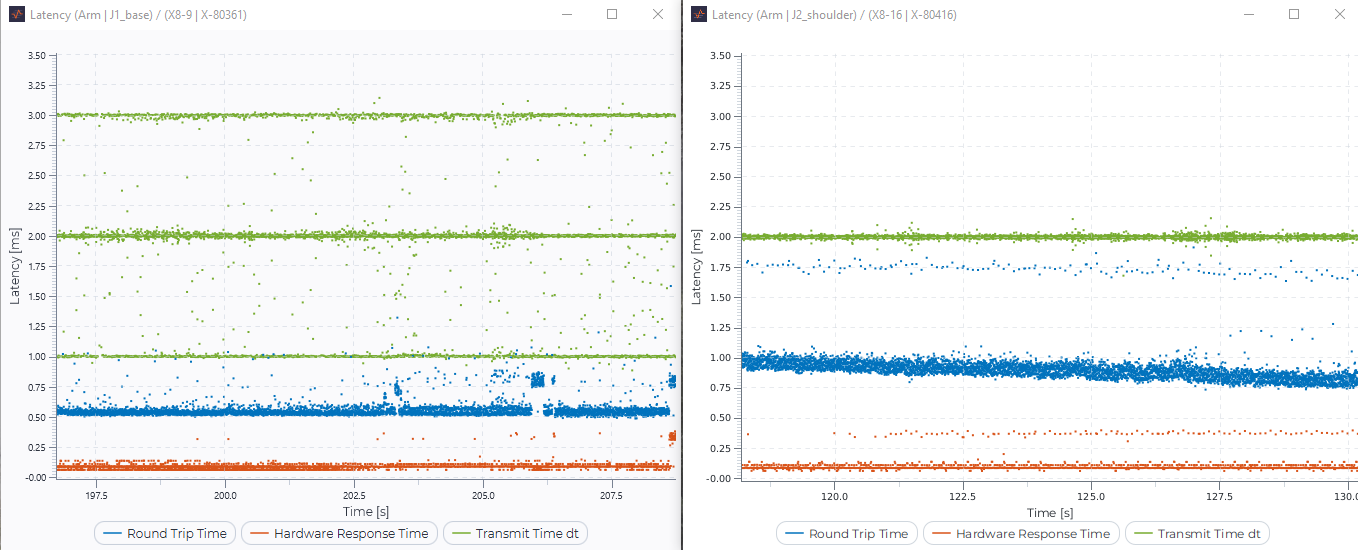

If you want to get an idea of the performance of the underlying network the Latency and Packet loss plots are useful. The image below shows a typical latency plot for a Windows 8 computer requesting feedback at 100Hz. The green dots represent the delta between received packets and provides information about the OS scheduler. The black dots represent the round-trip time of a packet going to and from a device.

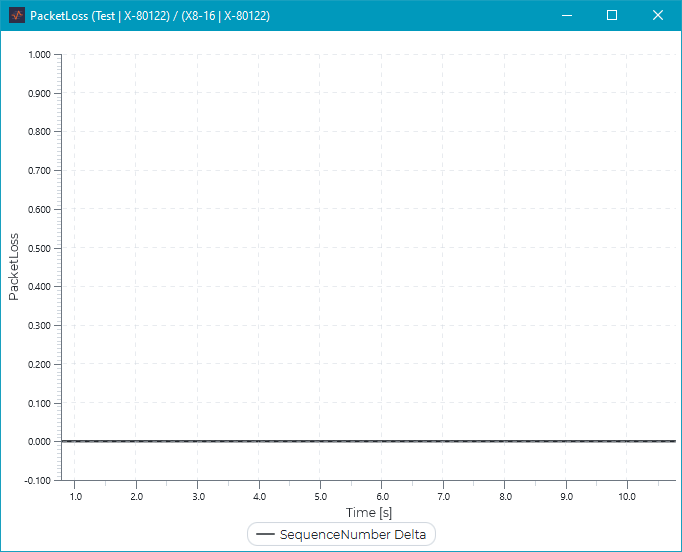

The packet loss plot should ideally show a solid line at zero. If there is frequent packet loss on a wired network (Wi-Fi is expected to have some amount of packet loss and jitter) or substantial spikes in latency there may an issue. For example:

-

Bad network connection, e.g., a network cable damaged or not plugged in correctly

-

The network is saturated, e.g., someone is copying files over the same network

-

The device is overloaded, e.g., someone is sending packets faster than a device can respond (e.g. open-loop commands from the API without pause or something else that limits the request rate)

-

The host computer is overloaded, e.g., there are too many applications running in the background

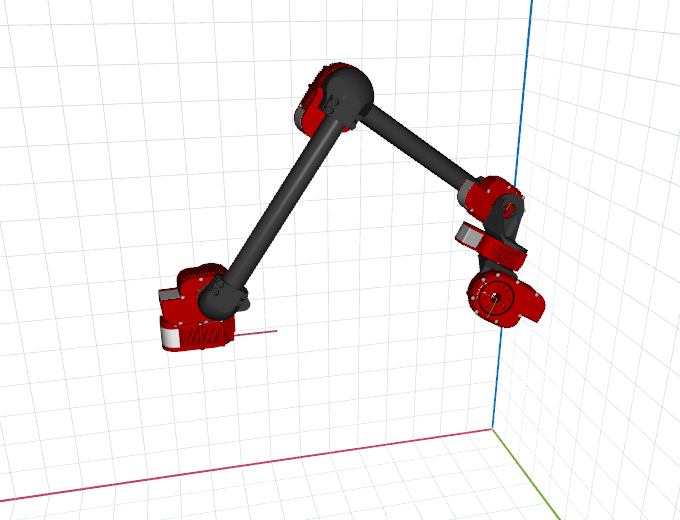

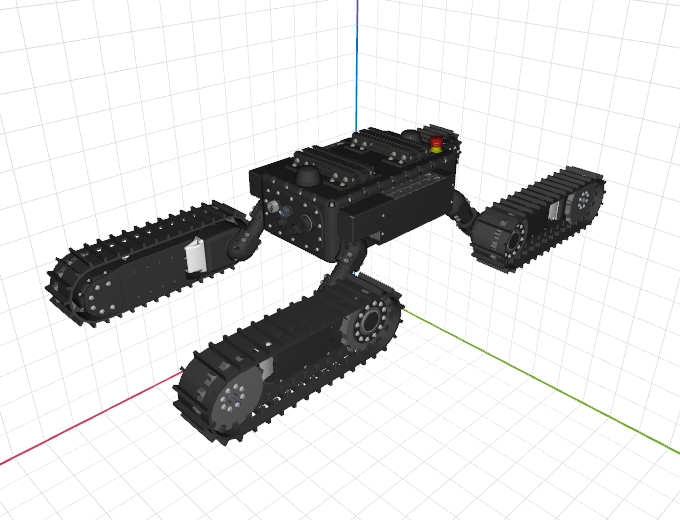

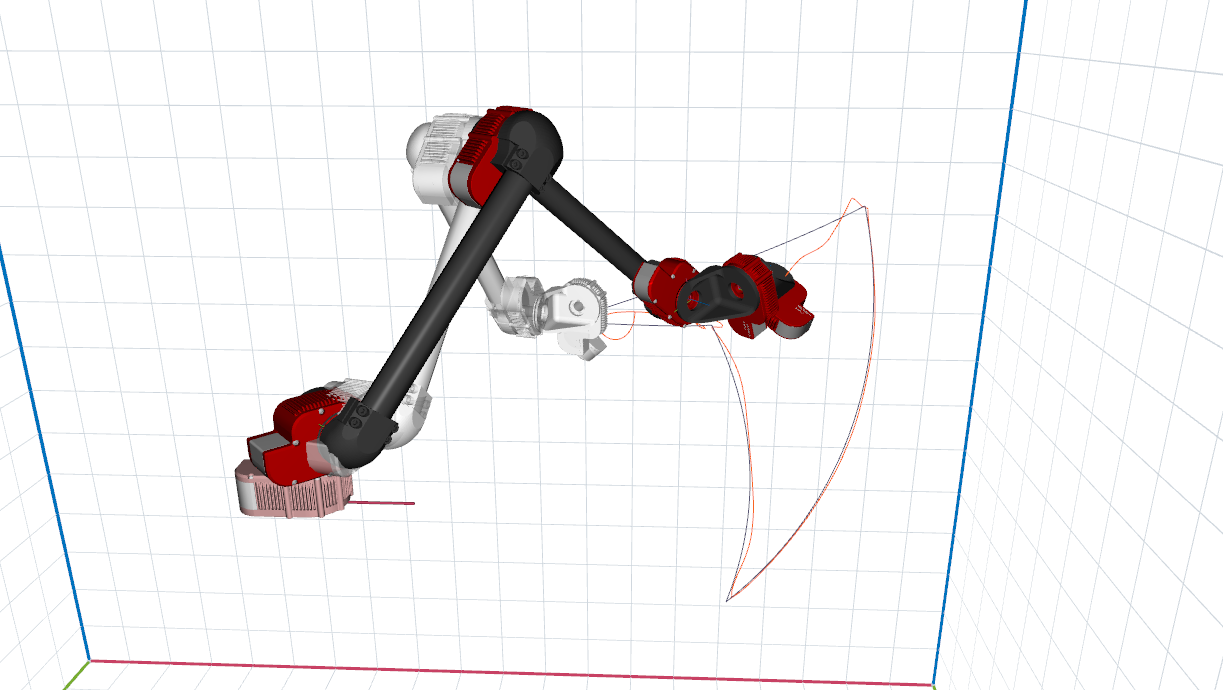

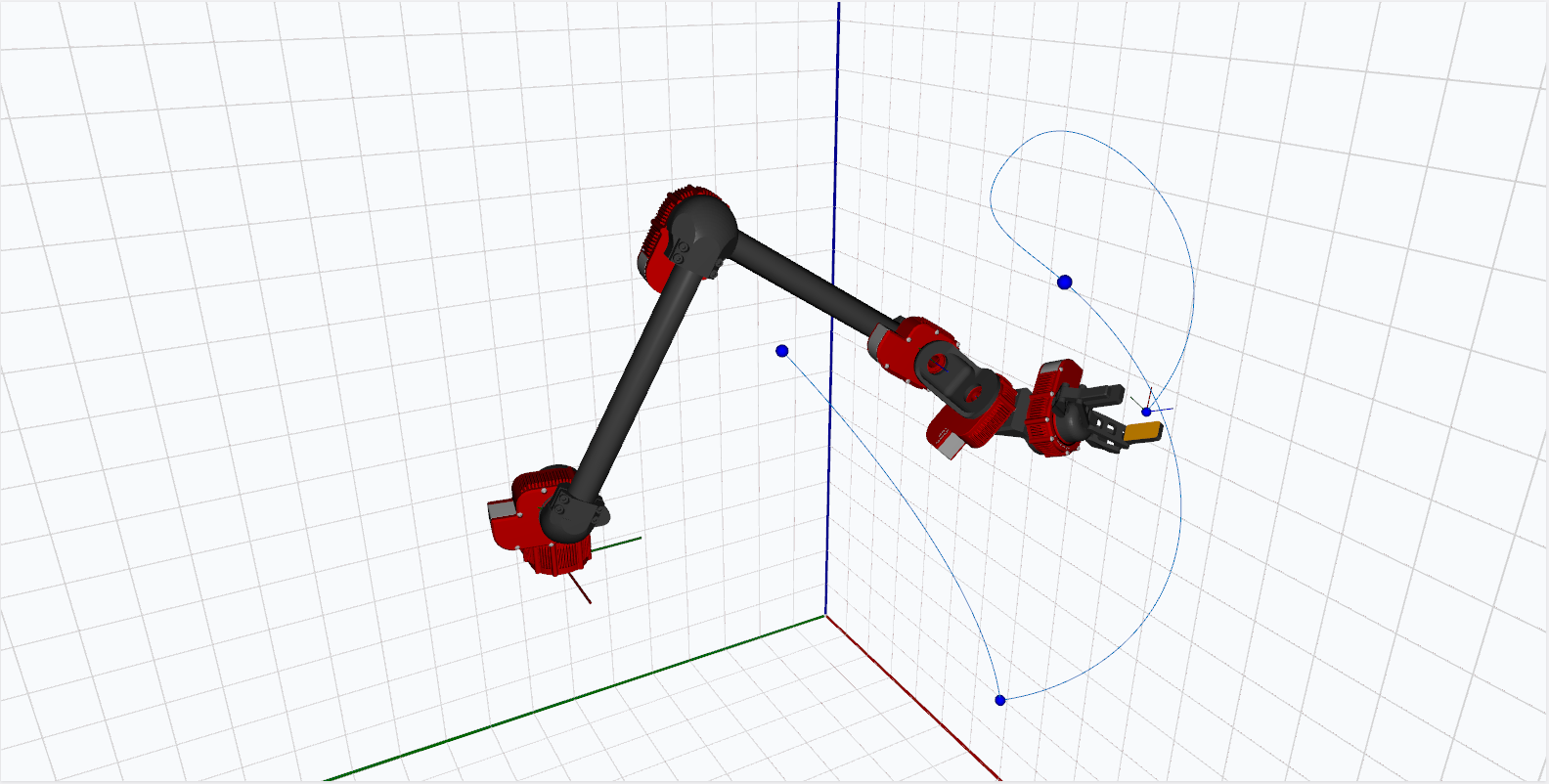

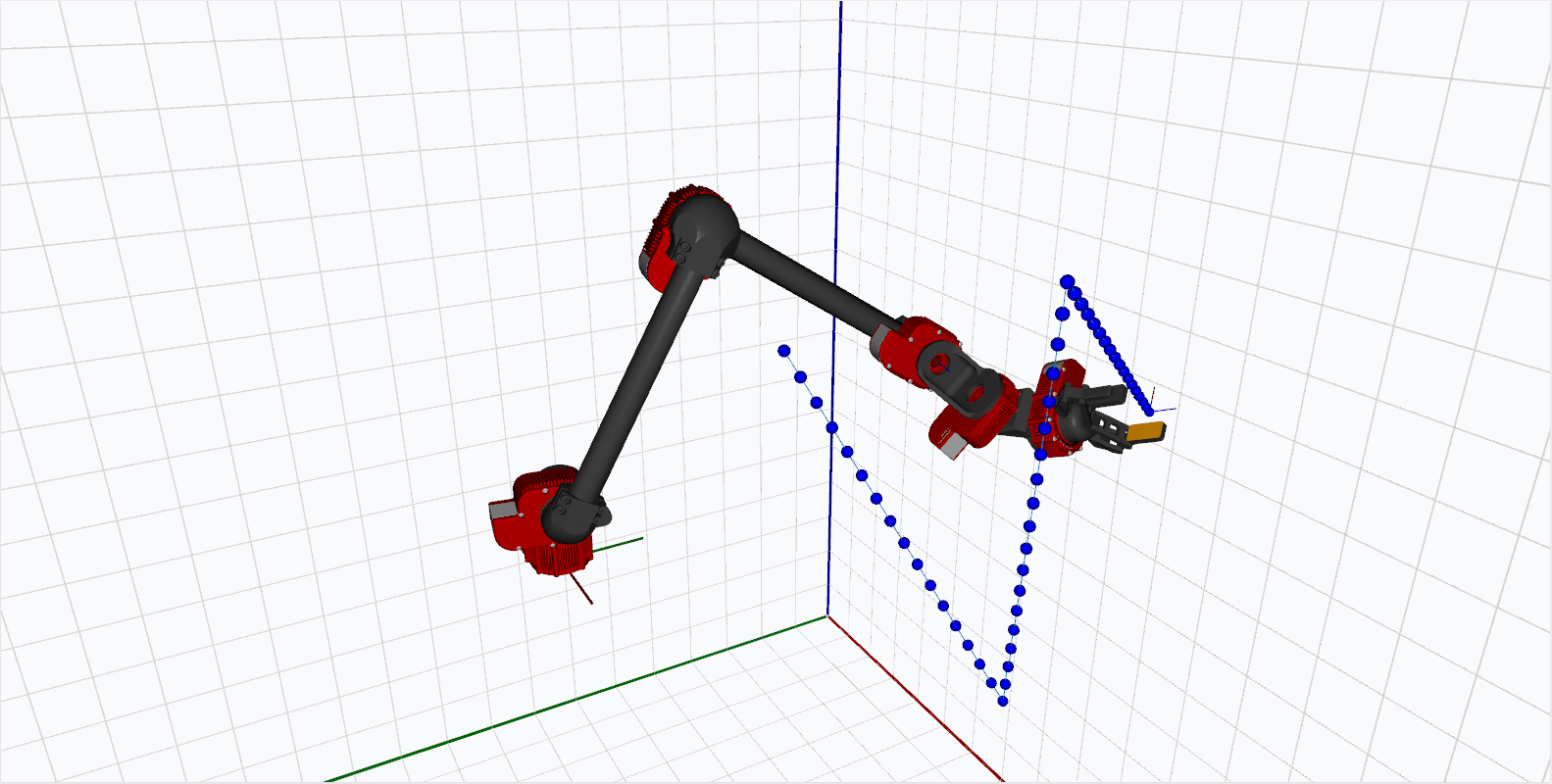

HRDF Viewer

View HRDF creates a 3D visualization of the specified .hrdf file. If devices are selected, the devices get mapped to the joints and create an online visualization of the robot configuration.

It also provides additional features such as displaying a command overlay or to orient the robot based on the first device’s IMU data. Please refer to the menu for more details.

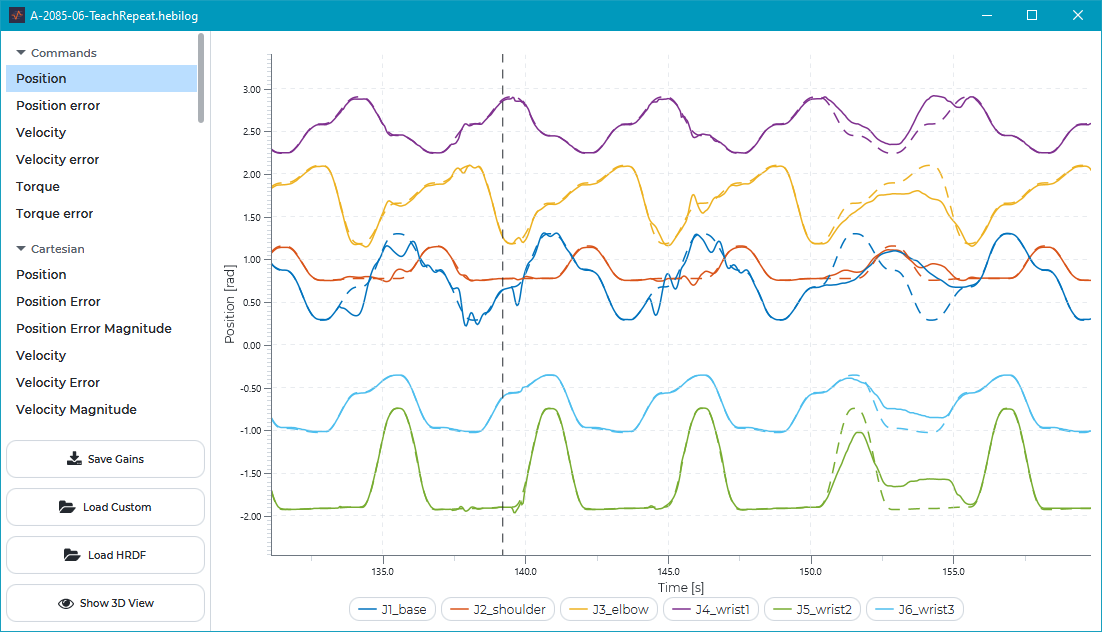

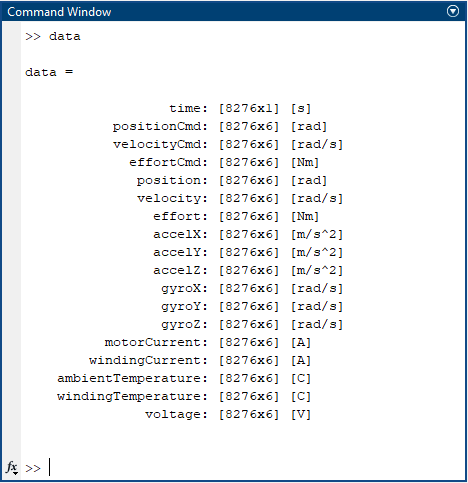

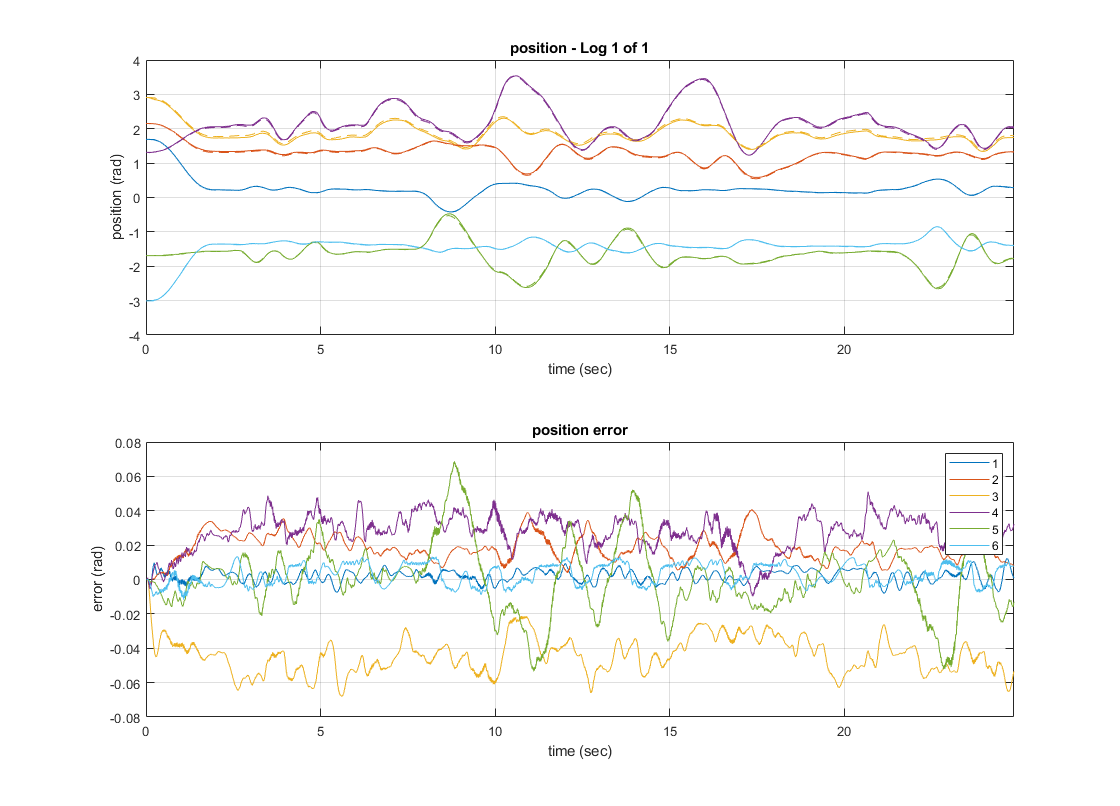

Log Viewer

View Log opens a log viewer that shows many useful plots and provides access to the logged gains.

Load HRDF lets users choose a matching HRDF file to get additional charts in end-effector coordinates as well as replay the contents in a 3D visualization.

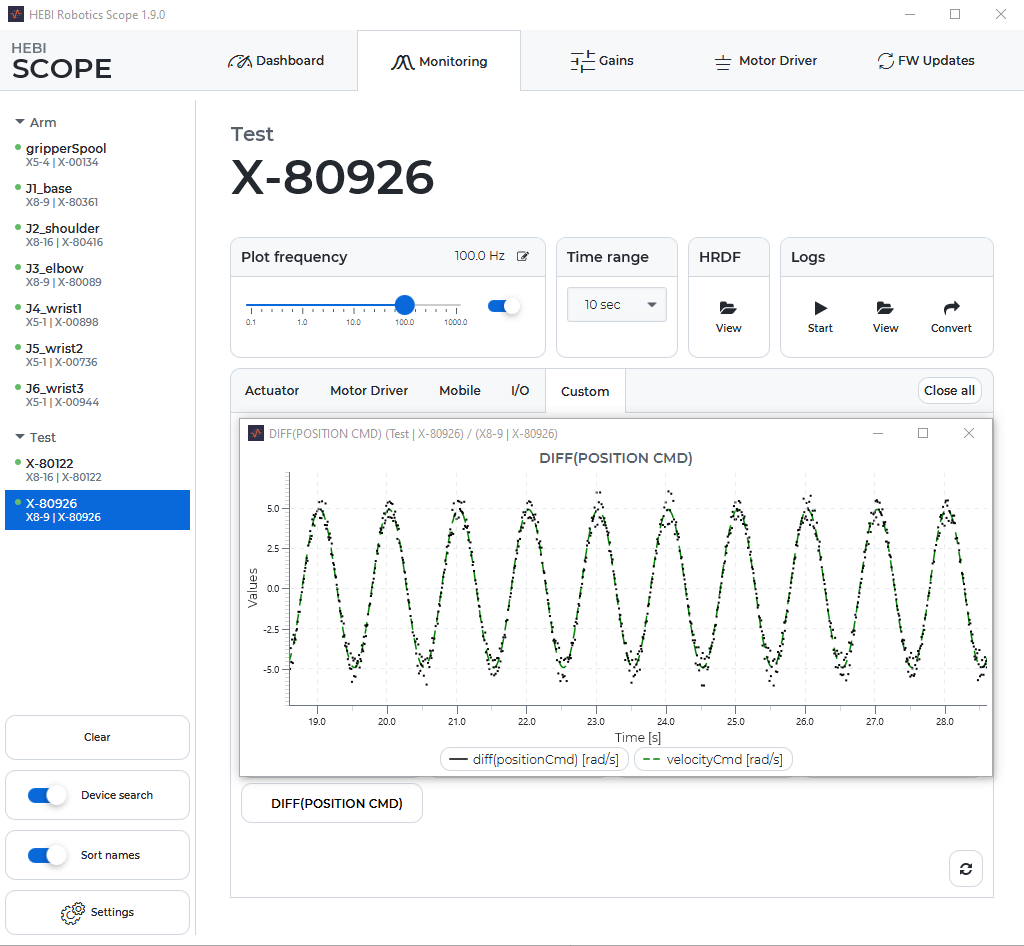

Custom Charts

It is also possible to create custom plots of feedback data. This is done by placing .XML files in the charts directory. The charts directory can be viewed and/or specified in the Settings menu.

The .XML file needs to have 2 elements, one <chart> and at least one <trace>. Valid files are loaded in alphabetical order and added as separate buttons in the Custom section of the Monitoring tab. The label that appears on the button matches the title attribute in <chart>.

<chart>

-

Attributes:

-

title: title for the button and plot header -

units: Y-Axis units -

max_samples: maximum rolling buffer size -

min_range: number, defaults to0 -

max_range: number, defaults to0 -

range_policy: behavior if trace values go out of range. Can befixedorexpanding(default).

-

-

Children:

-

<axis_x>: one or none. Defaults to a time axis -

<trace>: one or more. Each trace will be shown as a separate line.

-

<axis_x>

-

Attributes:

-

label: x axis label -

value: x values -

units: x axis units

-

<trace>

-

Attributes:

-

<label>: Name of this line in the legend -

<units>: Units -

<color>:-

red,green,blue,yellow,cyan,magenta,white,black(default), -

[0]default color for the specified index -

matlab[0]color for the specified index matching MATLAB’s default color scheme -

[x]/[y]/[z]colors used for XYZ charts,

-

-

<style>:solid(default),dashed,points -

<value>: A custom expression for calculating the current value. You have access to the latest feedback values (fbk) as well as the previous values (prevFbk). The field naming convention matches MATLAB, e.g.,fbk.positionorprevFbk.hwTxTime.

-

Examples

In custom charts you can use operators like + - * / to do basic math on different parts of module feedback. The example below creates a plot that calculates the position error, which can often be useful when tuning or evaluating the performance of a system:

<chart title="POSITION ERROR" min_range="-0.5" max_range="+0.5">

<trace label="Position Error" units="rad" color="black" style="dashed" value="fbk.position - fbk.positionCmd" />

</chart>The expression parser uses a Java compiler, so you may make use of math functions such as pow or sqrt. The example below calculates the magnitude of all three components of the accelerometer of a module.

<chart title="ACCEL MAGNITUDE" range_policy="fixed" min_range="0" max_range="20">

<trace label="sqrt(x^2 + y^2 + z^2)" units="" color="black" style="solid"

value="Math.sqrt(Math.pow(fbk.accelX,2) + Math.pow(fbk.accelY,2) + Math.pow(fbk.accelZ,2))" />

</chart>Additional lines can be added with addititional <trace> children. You can also access the previous feedback to perform diffs over a single timestep. The example below numerically differentiates the commanded position and compares it to the commanded velocity.

<chart title="DIFF(POSITION CMD)" min_range="-3" max_range="+3" range_policy="expanding">

<trace label="diff(positionCmd)" units="rad/s" color="black" style="points" value="(fbk.positionCmd-prevFbk.positionCmd) / (fbk.hwTxTime-prevFbk.hwTxTime)" />

<trace label="velocityCmd" units="rad/s" color="green" style="dashed" value="fbk.velocityCmd" />

</chart>

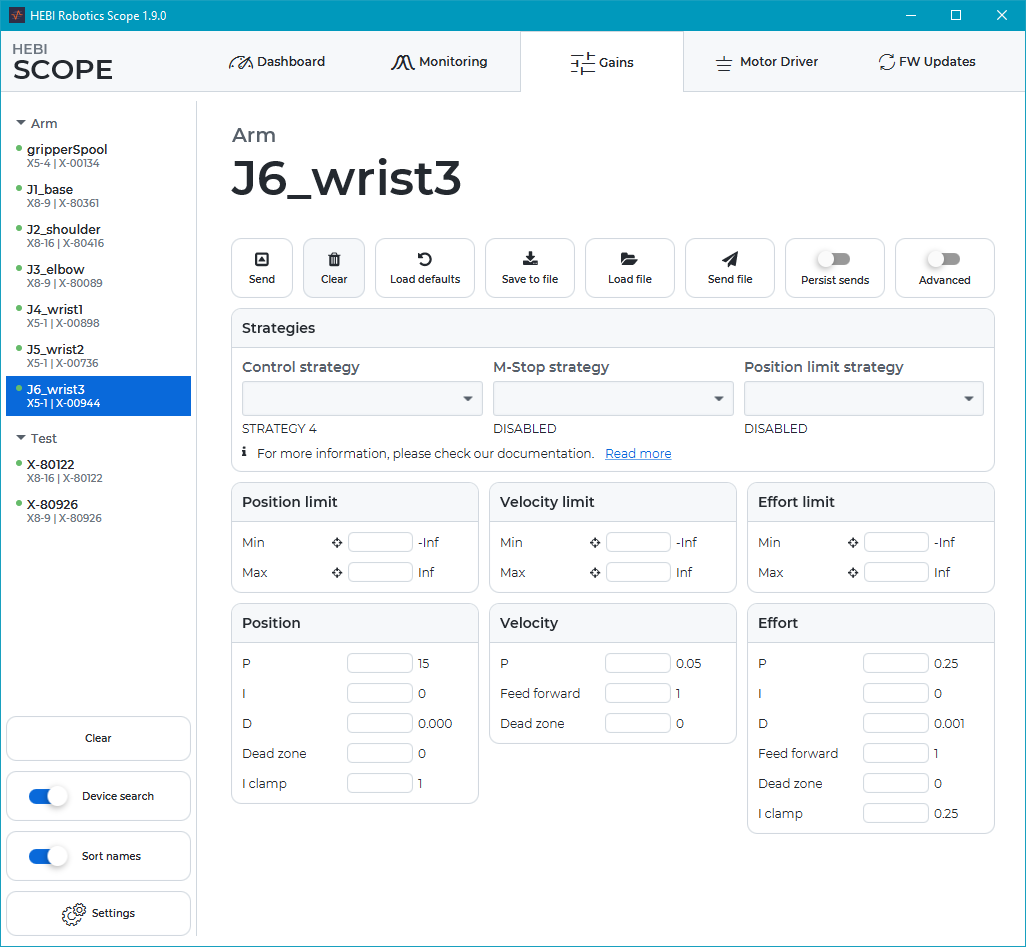

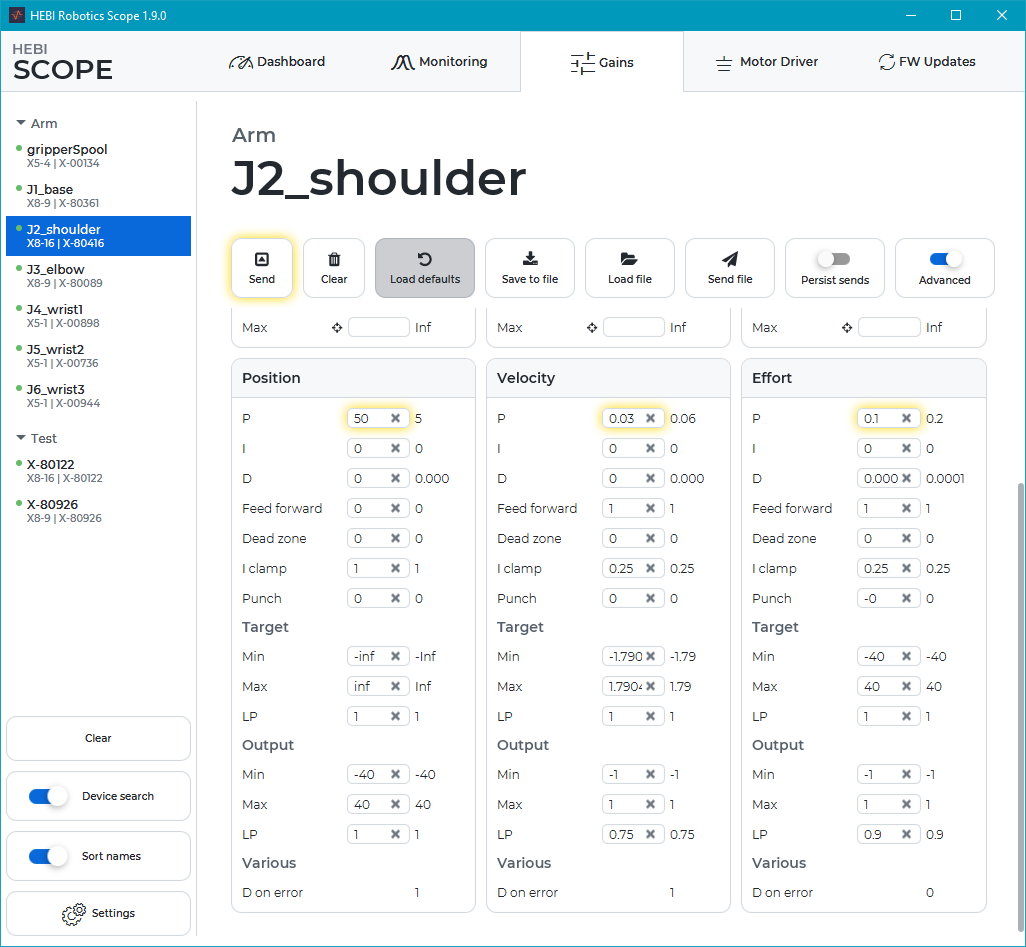

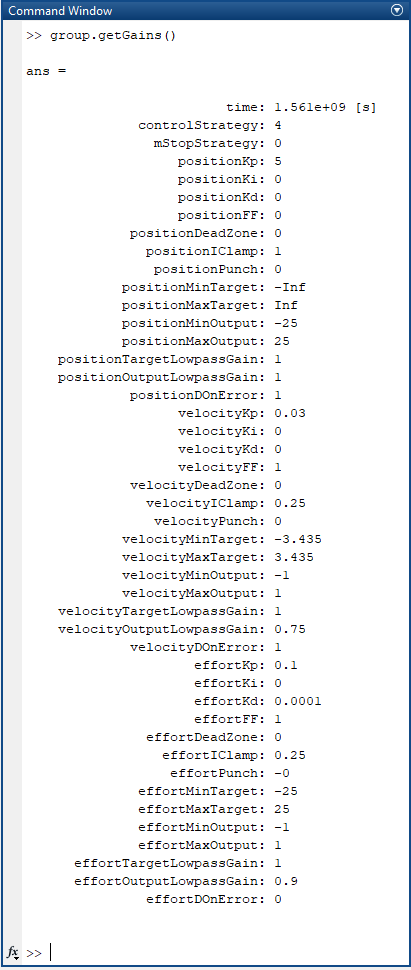

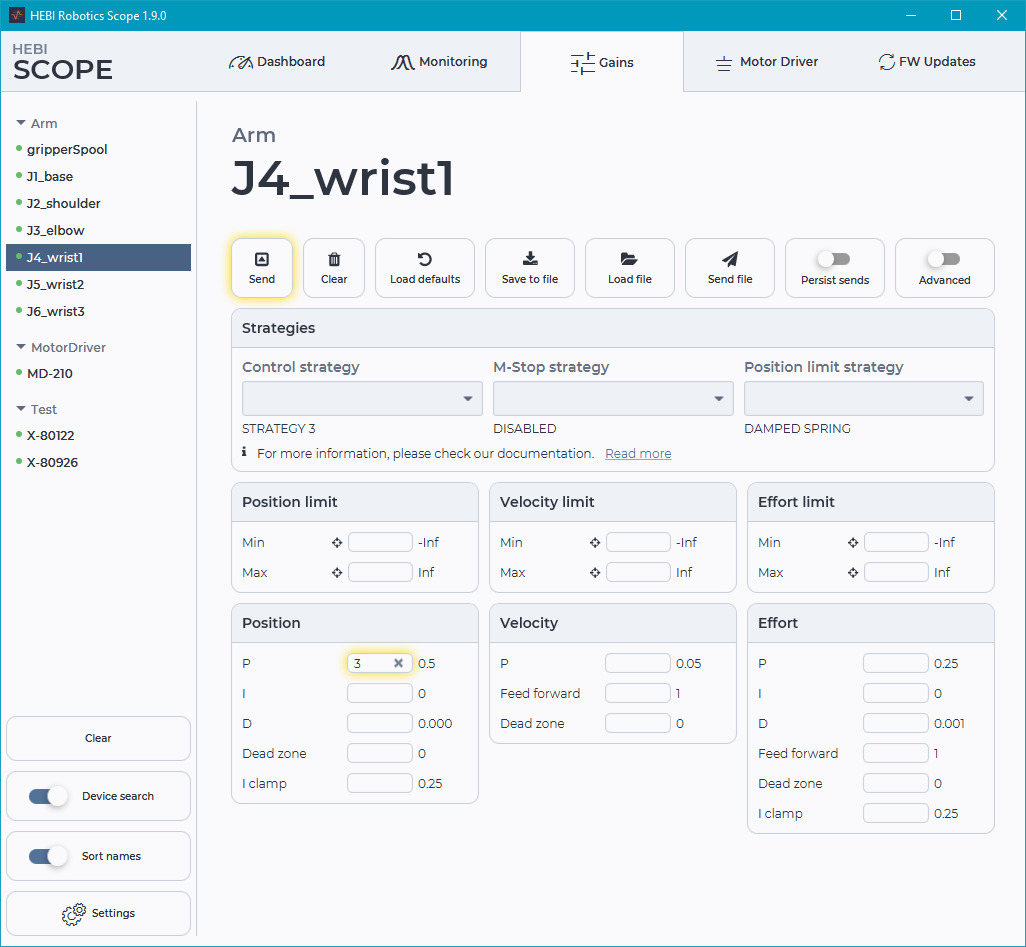

Gains Tab

The Gains Tab provides a convenient way to change control strategies, set safety limits, and to save and load gains. Tips and guidelines on tuning gains can be found in the Motion Control documentation.

Gains can be set while a device is actively being commanded, either by Scope or from any of the APIs, by clicking at any time. This allows easy online tuning of a robot’s motion. For example, you can generate commanded positions, velocities, and efforts for an actuator programmatically (e.g. in MATLAB or C++) and use Scope to change the gains and plot the tracking performance online.

If you are commanding from Scope you will need to make sure you are not also setting the control strategy (the dropdown box is blank). In this case the command will be cleared when sending gains.

Sending gains sends all the fields shown. Empty fields are ignored. You can clear the fields by clicking the Clear button.

The default view of Gains show some of the most commonly adjusted parameters for the position, velocity, effort controllers on an actuator. The full list of parameters can be viewed by toggling the Show Advanced switch. Details on all of these parameters can be found in the Motion Control documentation.

|

Gains are non-persisting parameters. This means that they will be reset to the last saved (persisted) values on reboot. To ensure that the current values are restored at next boot, you can enable the "Persist Sends" toggle or click |

Saving/Loading Gain files

Gains can be saved in a group-compatible gain format by selecting one or more devices and pressing the save to file button. The gains of multiple devices will be stored in the same order as they appear on the device pane.

Load file reads a gain file and loads the values into the corresponding input fields. Only one set of gains can be displayed at a single time.

Send File loads the gains of an arbitrary number of modules and immediately sends them to the selected devices, without populating the input fields. The order will again match the order in the device pane.

Resetting Gains

In many cases it is useful to reset or compare the active gains to the default values for an actuator. An easy way to do this is by using Load Defaults, which downloads the appropriate default gains for the selected hardware type and control strategy. Differences compared to the active gains are highlighted in yellow.

|

Loading the default gains for a module requires an active internet connection. For cases that do not have access to the internet, we provide downloadable default gains that can be stored and loaded offline. |

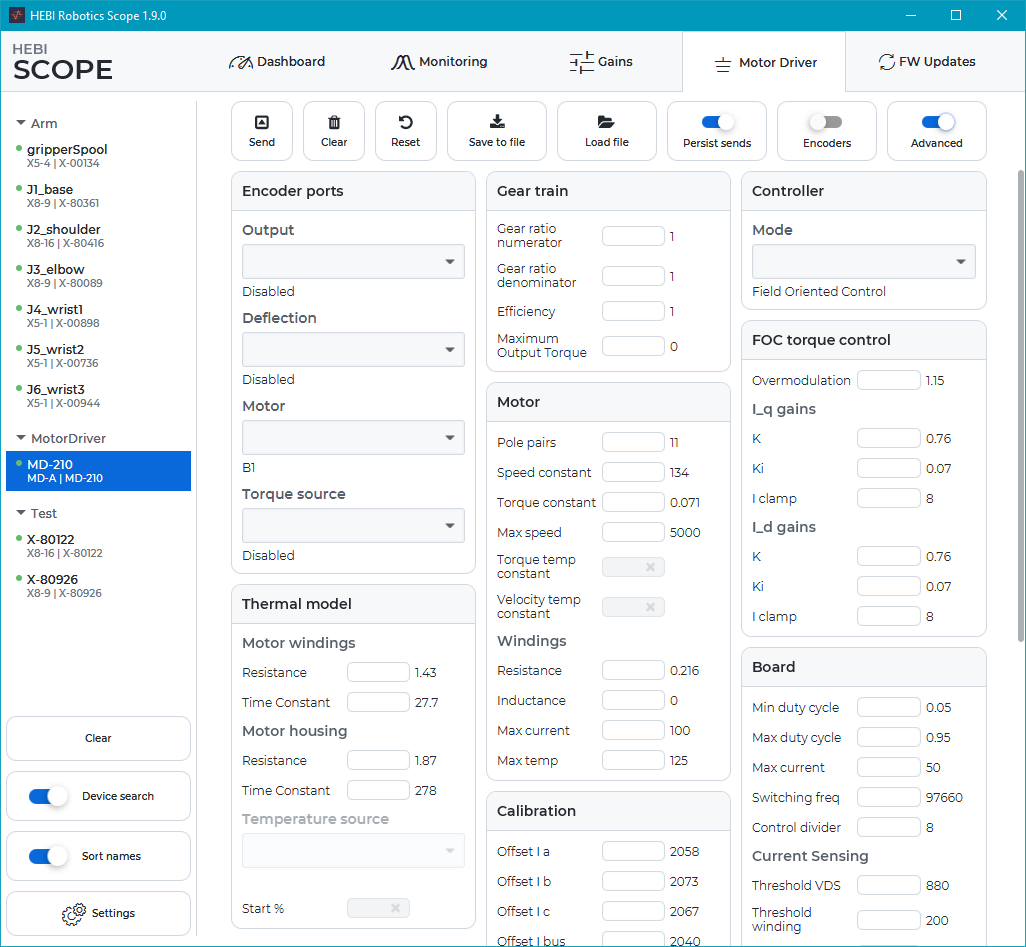

Motor Driver Tab

The motor driver tab provides control of parameters related to turning a custom encoder and motor into a HEBI compatible actuator. Please refer to the built-in tooltips for more information on the individual fields.

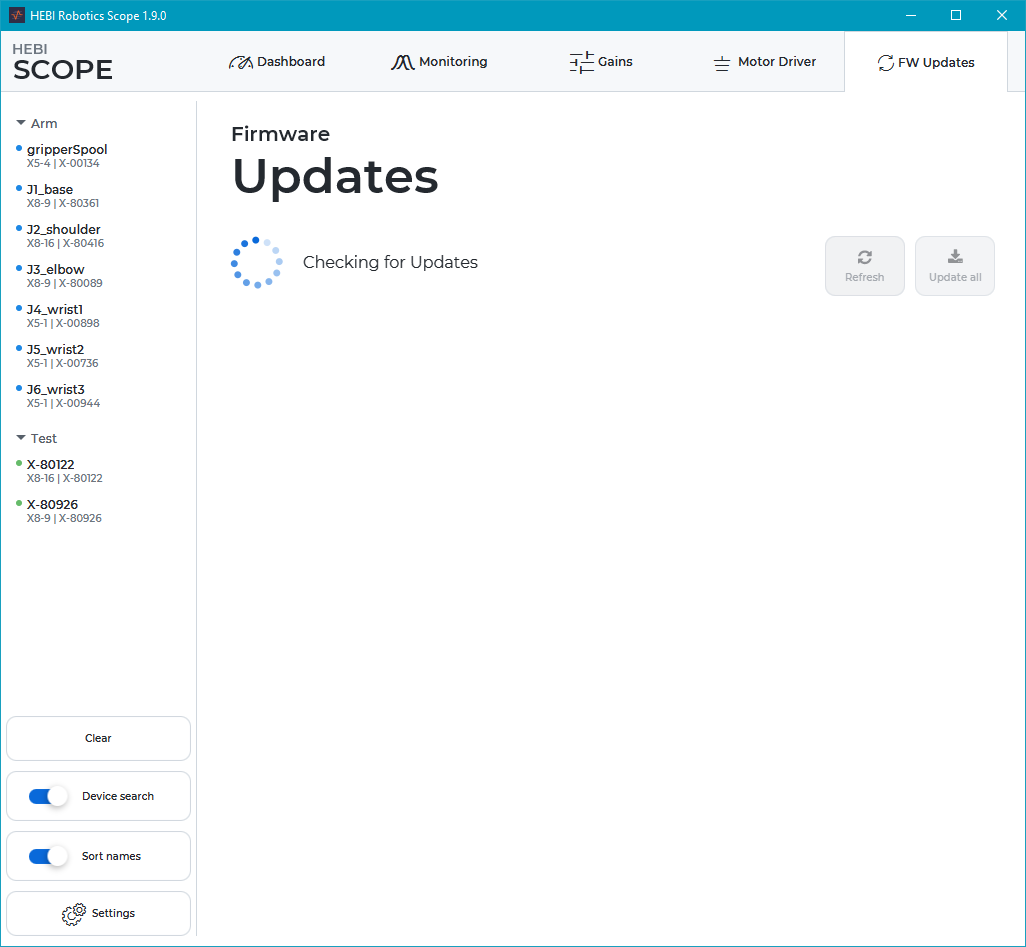

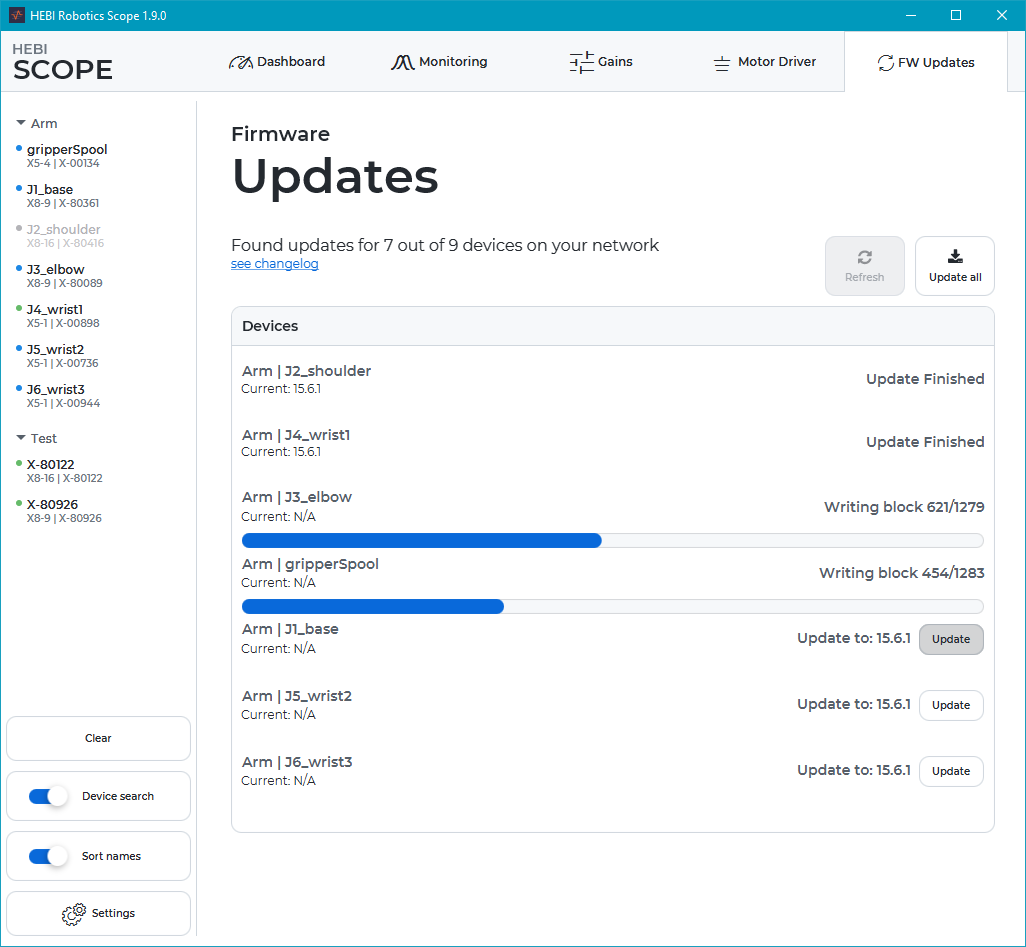

Updating Firmware

HEBI releases updates to the internal device firmware that contain performance improvements, additional features, and bugfixes. Each device has an isolated Bootloader mode, so updates can be done safely without the risk of disabling a module. You can check for updates using the Refresh button. Updating firmware requires an internet connection.

We strive to maintain backwards and forwards compatibility in firmware udpates. In the rare cases where we do break backwards compatibility, we will send out email notifications to all customers. If you have any concerns about a firmware update, please check the Firmware Changelog or email us at support@hebirobotics.com.

|

The refresh will show all modules for which updates are available. You can then update individual devices, or all of them at once. The devices will automatically reboot into Bootloader, download the appropriate application firmware, and reboot.

Updating a device should take about 10 seconds. Cancelling or interrupting an update will not "brick" the module, but may require you to run the update process again.

Scope CLI

Scope ships with an additional command line interface (CLI) that provides useful file loading and configuration utilities without requiring the graphical interface. On Windows and Linux the command line tools are installed automatically. On macOS you need to click Add to shell path in the macOS specific settings.

hebi-config

The hebi-config tool can send configuration files to specified devices. Calling hebi-config --help prints a detailed list of all available parameters.

For example, sending a motor driver configuration to a named device looks like this

hebi-config --name MD-210 --motor-driver path/to/MD-210.xml --persist --resetMultiple entries can be added multiple times or in comma separated lists

hebi-config --name J1_base --name J2_shoulder --names J3_elbow,J4_wrist1,J5_wrist2, J6_wrist3 --gains path/to/arm_gains.xmlhebi-gateway-server & -client

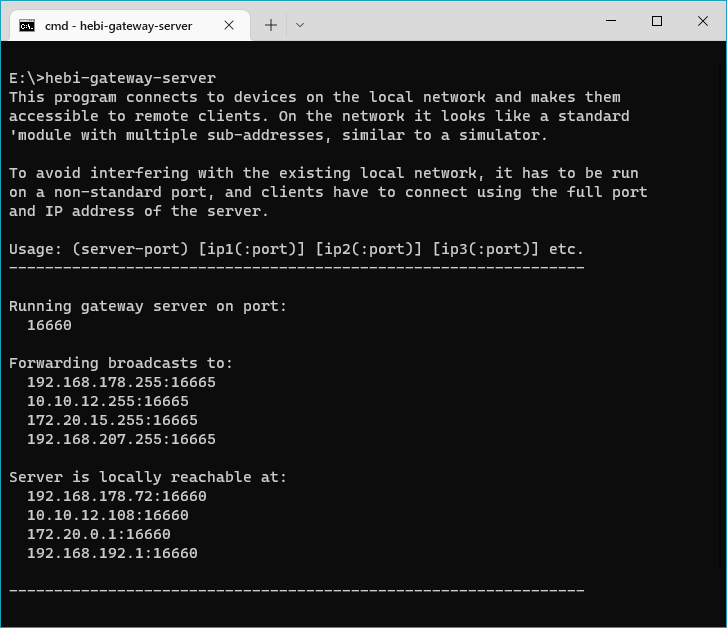

It is sometimes desired to connect to devices on a remote network through tunnels or VPNs. Broadcasts are generally limited to the local network, so we developed a Gateway connection that can forward local lookup requests to remote networks. With this feature, if computer 1 is running the gateway, a secondary computer 2 can connect to and interact with the devices located on computer 1’s network as if they were local to computer 2.

There are two utilities, hebi-gateway-server and hebi-gateway-client that serve two different use cases.

The hebi-gateway-server connects to one or more unicast or broadcast ip addresses and exposes all discovered devices on the server port (defaults to 16660). In a VPN scenario, this application would run on the remote network and allow remote lookups.

The tool prints out a Server is locally reachable at section that lists all the available addresses of the remote host.

The hebi-gateway-client connects to one or more addresses (port 16660) and exposes found devices on the default device port, where they can be seen by lookups with the default settings.

In the VPN scenario, this application would run on the local network and connect to one of the lookupAddresses shown in the hebi-gateway-server. However, note that the client is functionally equivalent to manually adding the remote addresses to Scope or the APIs, so it is not technically required.

In case you are not familiar with setting up VPNs, we recommend taking a look at ZeroTier. It can setup a private network with bi-directional communications between multiple individual computers across the Internet.

Multiple HEBI device emulation apps on one host

Some of our applications, e.g., imitation groups or simulator devices, emulate a physical device interface that needs to listen on the default udp port in order to be found by Scope or API lookups. Due to port limitations, each port may only be bound to one application.

If you for some reason need to run multiple emulator apps, e.g., imitation and a joystick interface, you can run them on different ports and combine them using hebi-gateway-client.

For example, you can select custom port 2800 in the imitation device interface, and run hebi-gateway-client 127.0.0.1:2800.

WSL2 Gateway

Windows Subsystem for Linux v2 (WSL2) lets Windows users run a GNU/Linux environment that is very tightly integrated with the host OS. While the Linux versions of the HEBI APIs and tools can run without modification, the environment runs inside a virtual machine that is on a separate network and prevents any devices from being seen.

Until WSL2 adds features to expose raw network interfaces, this limitation can be worked around by (1) launching the VPN Gateway on the Windows side,

# run on Windows

hebi-gateway-serverand subsequently (2) adding the shown IP address on the WSL2 Linux side.

| Scope with basic plotting capability can be run using X-forwarding. For setup instructions please refer to How to set up working X11 forwarding on WSL2. |

When you run code on WSL2 you can expect the frequency to track significantly better (green dots) at the cost of slightly higher latency (blue dots) due to the additional indirection. The charts below show latency plots running simultaneously on the same computer on Windows (left) and Ubuntu 20.04 on WSL2 (right):

hebi-video

The video acquisition tool for Scope’s video stream viewer is packaged as a separate app due to size concerns. You can download the latest release.

| Downloading the HEBI Video .exe application from the link above will install all of the files required to run the commands below from your OS command terminal. |

Video streams can be acquired from different sources, including Webcams, IP-cameras, or video files. The stream acquisition updates a memory mapped file, which can simultaneously be viewed in Scope and be opened in an API. Streams can be restarted or changed at any time and do not crash the viewer.

Below are some examples for different sources:

# Syntax

openStream {outputFile} {source} ({width} {height} {fps})

# First USB camera on Windows at 1920p resolution

openStream usb0.stream 0 1920

# Streaming an input file

openStream file.stream recordedVideo.mp4

# Stream from an IP-camera using rtsp

openStream ipcam.stream rtsp://${user}:${pw}@${ip}/stream0The acquisition is configured to prefer low latency over saving computation time or reducing artifacts. openStream is based on bundled versions of FFMpeg and OpenCV, and is using software decoding.

The package also bundles a GStreamer based OpenGStreamerStream with support for hardware decoding for improved latency. Depending on your system you may need to install the GStreamer library (see instructions).

# Stream from an IP-camera using rtsp w/ possible hardware decoding

OpenGStreamerStream ipcam.stream rtsp://${user}:${pw}@${ip}/stream0Using hebi-video with the HEBI CR1 Camera Module

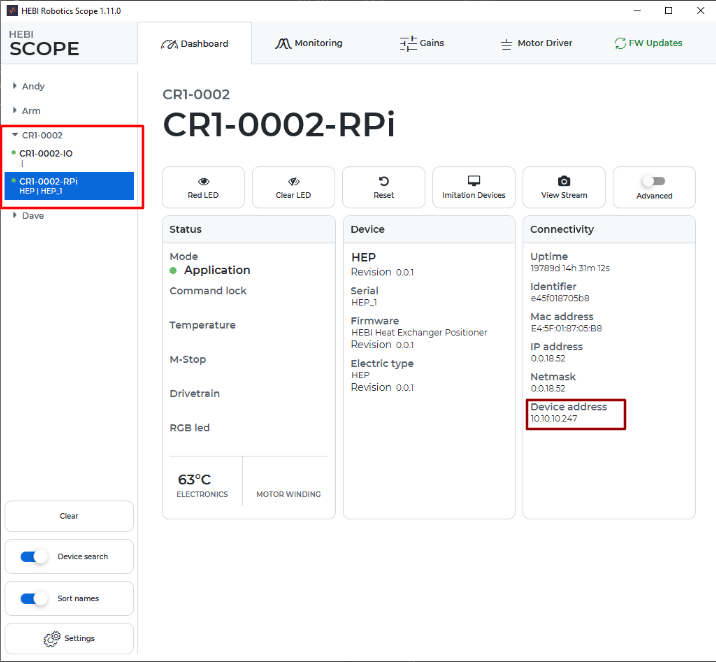

HEBI Camera Modules use RTSP to stream the camera feed over the network connection. In order to visualize the camera stream, determine the IP Address of the RPi in the Camera Module through Scope as shown below.

Once you have located the RPi IP Address, use it with the following command:

# Stream from a HEBI RPi Camera Module

openStream CR1.stream rtsp://{ip}:8554/test

# Example with IP shown above

openStream CR1.stream rtsp://10.10.10.247:8554/testRunning this command will generate a .stream file that scope can use to view the stream with the View Stream button.

Mobile I/O

HEBI Mobile I/O is a free app for iOS and Android that provides a way of using a mobile device to generate general-purpose input/output in the HEBI APIs. Its main feature is a touch-screen interface that mimics a game-controller layout and provides digital and analog feedback in the same format that you would read from the HEBI I/O Board. The app also exposes internal sensors, including the mobile device’s IMU, magnetometer, GPS-based location data, and on compatible devices it provides the estimated 6-DoF pose of the device using ARKit in iOS and ARCore in Android.

Getting Started

-

Get the app for free from:

-

Make sure the mobile device is connected to your local network.

-

Launch the app.

-

In order to get pose feedback based on ARKit/ARCore, you will have to allow the app to access the device camera. This is because ARKit uses the camera to track features in the world to estimate the devices full 6-DoF pose.

-

-

Access feedback from the mobile device in Scope or any of the APIs.

-

Matlab Examples (Github)

-

Python Examples (coming soon)

-

C++ Examples (coming soon)

-

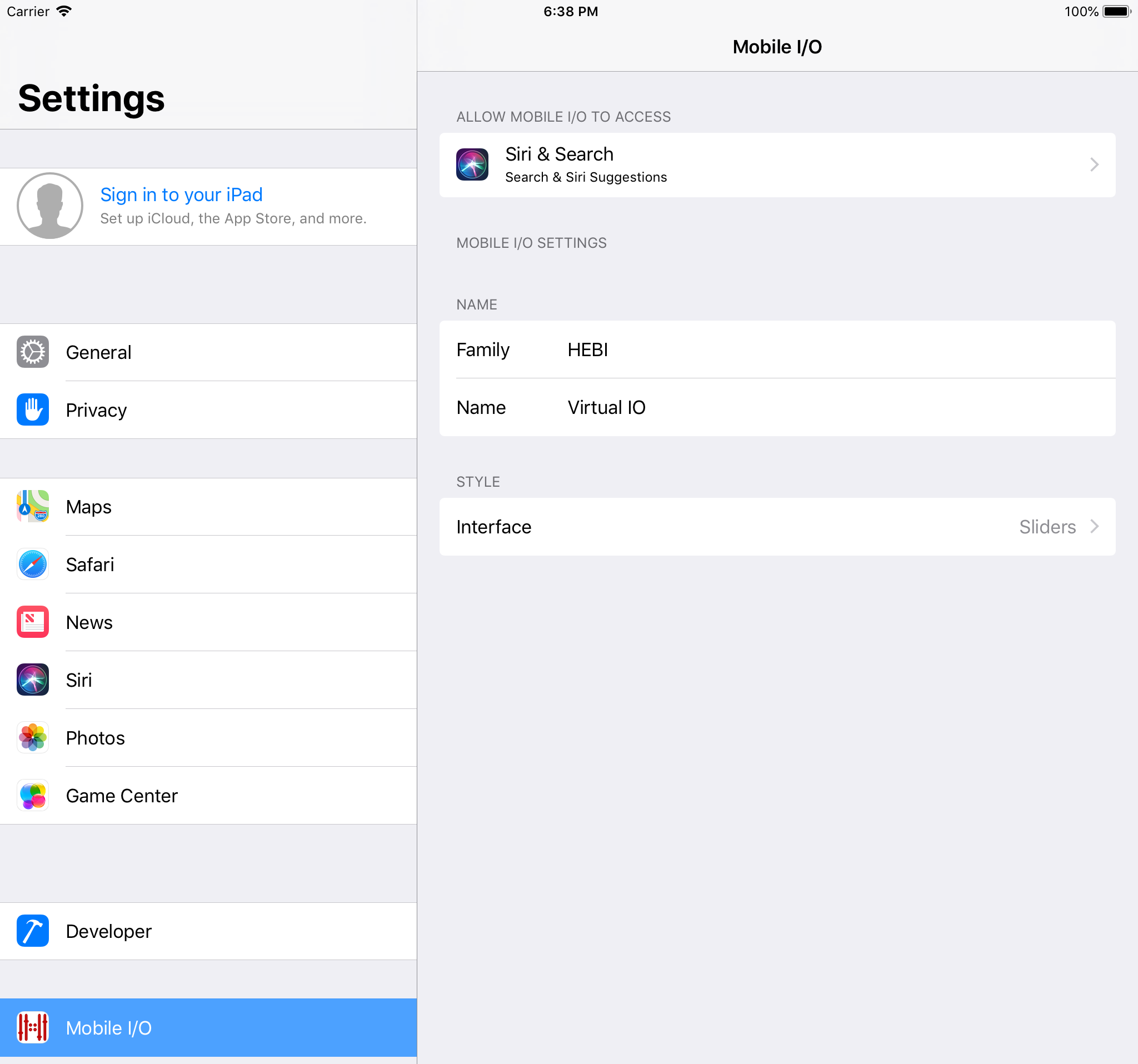

App Settings

In both Android and recent iOS versions, the name and family of the mobile device can be set using Scope by right-clicking the mobile device on the left side panel, or by setting the name and family from any of the APIs.

Android

There are also switches in the app to enable/disable GPS location feedback and ARCore pose feedback.

iOS

In iOS the name and family of the mobile device can be set in the settings panel for the app, found going to iOS Settings, and scrolling down the app list until you see Mobile I/O. This name and family will be how the device appears in Scope and the APIs. You can also change the layout of the iOS app to an alternative portrait Sliders view, instead of the default landscape Joystick layout. Finally, you can select whether or not the acceleration feedback that is returned from the application includes the acceleration due to gravity, or filters this information out.

Joystick View

The joystick layout of the app provides 8 buttons and up to 8 analog sliders or joystick axes that you can use for input. The way the APIs communicate input from these buttons and axes are detailed in the table below. The buttons and axes are labeled on the screen. Note that the layout of the buttons and sliders may differ depending on the device.

Device Feedback

Overall, the API provides access to feedback from a mobile device the same way it does for other HEBI modules. Its main feature is a touch-screen interface that mimics a game-controller layout and provides digital and analog feedback in the same format that you would read from the HEBI I/O Board.

The Mobile I/O app also returns other sensor data, including the full 6-DoF pose of the device calculated using ARKit / ARCore on supported. The feedback availability, accuracy, and precision will depend on the device and operating system. 3

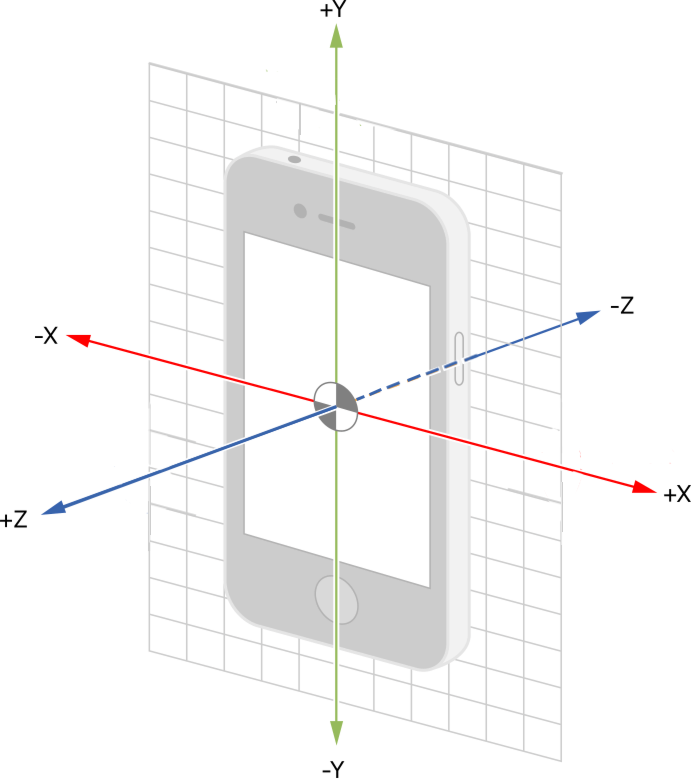

Reference Frame

Where applicable, the reference frame for the feedback from the device follows the convention of the iOS Core Motion framework (see image below).

I/O Feedback

| Parameter | Units | Description |

|---|---|---|

|

|

The current time from the system clock used by the API. This is a single value that corresponds to all feedback at this timestep. |

|

|

The system time when feedback was received by the device. The most recent of these times is what is reported as the single |

|

|

The system time when feedback requests were sent to the device. |

|

|

The hardware timestamp when the device transmitted its feedback. Time initializes at 0 when the app is launched. |

|

|

The hardware timestamp when the device received a request for feedback. Time initializes at 0 when the app is launched. |

|

|

8 analog inputs based on touch input from joysticks or sliders in the app. |

|

|

8 digital inputs based on touch input from buttons in the app. |

Mobile Feedback

| Parameter | Units | Description |

|---|---|---|

|

|

The current time from the system clock used by the API. This is a single value that corresponds to all feedback at this timestep. |

|

|

The system time when feedback was received by the decice. The most recent of these times is what is reported as the single |

|

|

The system time when feedback requests were sent to the device. |

|

|

The hardware timestamp when the device transmitted its feedback. Time initializes at 0 when the app is launched. |

|

|

The hardware timestamp when the device received a request for feedback. Time initializes at 0 when the app is launched. |

|

|

The device’s estimated linear 3-DoF acceleration from an internal IMU, excluding gravitional acceleration. Depending on the API, XYZ values are combined together into a single vector or returned individually. |

|

|

The device’s sensed 3-DoF angular velocity from an internal IMU. Depending on the API, XYZ values are combined together into a single vector or returned individually. |

|

|

The device’s sensed 3-DoF magnetic field from an internal magnetometer. Depending on the API, XYZ values are combined together into a single vector or returned individually. |

|

|

Altitude reported by the device barometer. Not yet supported. |

|

|

The device’s 3-DoF orientation, based on Core Motion in iOS and the equivalent motion sensor APIs in Android. Depending on the API, quaternion components are combined together into a single vector or returned individually. |

|

|

Latitude position on the surface of the earth, as reported by the device location services, which includes GPS. Currently Android only. |

|

|

Longitude position on the surface of the earth, as reported by the device location services, which includes GPS. Currently Android only. |

|

|

Altitude above sea level, as reported by the device location services, which includes GPS. Currently Android only. |

|

|

The bearing of the horizontal direction of travel of this device, based from true north. Currently Android only. |

|

|

The standard deviation of the uncertainty of the horizontal lat/long position of the device. Currently Android only. |

|

|

The standard deviation of the uncertainty of the vertical altitude of the device. Currently Android only. |

|

|

The GPS time when feedback was received for GPS-related feedback. Currently Android only. |

|

|

The device’s orientation in the world, based on ARKit / ARCore. Depending on the API, quaternion components are combined together into a single vector or returned individually. |

|

|

The device’s position in the world, based on ARKit / ARCore. Depending on the API, position components are combined together into a single vector or returned individually. |

|

|

Status of the tracking from ARKit / ARCore.

The values listed here are used for Scope and the Matlab API. In other APIs they are an |

|

|

Charge level of the device’s battery (in percent). |

Info Feedback

| Parameter | Units | Description |

|---|---|---|

|

|

The current user-settable name that a device shows up as in a |

|

|

The current user-settable family that a device shows up as in a |

|

|

A unique identifier of the device, displayed in the format of a MAC address. This is not the actual MAC address of the device. |

|

|

The IP Address of the device. |

|

|

The network mask of the device. |

|

|

The gateway of the device. |

|

|

The unique identifier of the device provided by iOS. |

|

|

The class of device, e.g. |

|

|

The specific revision of the device, e.g. |

|

|

The operating system of the device, e.g. |

|

|

The version of the operating system, e.g. |

|

|

The name of the app. |

|

|

The version of the app. |

Device Commands

The Mobile I/O applications also can be configured by and display/react to commands sent from Scope or the APIs.

I/O Commands

| Parameter | Units | Description |

|---|---|---|

|

|

Sets the "snap to" location for a joystick axis (default 0) or slider (default disabled). Sending |

|

|

Sets the button behavior to momentary (default, 0) or toggle (1). The toggle state is identified by white text on the button, whereas the momentary state is black. |

|

|

Illuminates (1) or hides (0) a indicator ring around the corresponding button. |

|

|

If a joystick axis or slider is not in "snap" mode, and is not actively being moved, then this moves the joystick axis or slider to the given location. For joystick commands that are out of the unit circle range, this projects the desired point back to the unit circle. |

General Commands

| Parameter | Units | Description |

|---|---|---|

|

|

Sets the color of a border around the outside perimeter of the app |

|

|

For non-zero commanded values, causes the app to vibrate momentarily (on supported devices) |

HEBI Input

The HEBI Input program is a small python script that runs on computer, exposing the inputs of a connected joystick or gamepad as a HEBI IO board device. In this way, you can use the Mobile IO wrapping classes available in the HEBI APIs to access and react to the joystick controls in the same way as using the Mobile IO app as an input device.

Note that this cannot be run at the same time from the same computer as the "imitation group" feature within Scope, as these bind to the same network port.

Getting Started

-

Download the zip from here:

-

HEBI Input (.zip)

-

-

Extract into a local directory

-

Install the dependent packages by running

python3 -m pip install -r requirements.txt -

Modify the

keymap.ymlto match the input events for the joystick/gamepad you are using; this mapping may vary depending on the host OS. We provide a keymap for the Voyee XBox clone gamepad. -

Run

-

Mac/linux:

./controller_mobile_io.py --key_config <controller yaml file> --family <DesiredFamilyName> -

Windows:

python3 controller_mobile_io.py --key_config <controller yaml file> --family <DesiredFamilyName>

-

The joystick should now be visible to devices on the same network through Scope; you can view the feedback in real time by going to the "I/O" sub-tab of the "monitoring" tab.

You can pass the --name parameter to adjust the initial name, or the --port parameter to change the default port that is used (e.g., to use multiple instances simultaneously in conjunction with the hebi-gateway-client tool).

You can view all the command line options for the current version by running python3 controller_mobile_io.py -h

Device Feedback

Overall, the API provides access to feedback from the HEBI input script in the same way it does for other HEBI modules. The primary benefit is providing an interface to the joystick without requiring code changes on the control software side or any third-party libraries. The feedback is exposed in the same format that you would read from the HEBI I/O Board.

HEBI APIs

HEBI provides libraries and programmatic APIs that enable users to control complex systems in real-time directly from MATLAB, Python, or C. These APIs are designed to have parallel features, although syntax varies slightly between language. The flexibility allows the user to work in the environment they are most comfortable with and which matches the system requirements. For example, MATLAB and Python can be used for fast prototyping and testing of algorithms on real hardware without the need for compilation and code generation; both are fast and powerful enough for delivering a final software solution. Alternatively, C can be used to compile an application to run with a small footprint within a deployed linux system.

MATLAB

MATLAB is a proprietary scripting language and computing environment developed by Mathworks. It is widely used for data analysis and research across many engineering disciplines. The language’s focus on linear algebra and matrix operations makes it a very good language for programming robots.

| We currently do not officially support Simulink. For more details, please refer to the Simulink Support thread on the forums. |

Python

Python is an easy-to-learn, powerful general purpose programming language with broad package support that makes it useful for beginners as well as for advanced applications.

C++

C++ is a powerful, general purpose advanced programming language. It has a steeper learning curve than Python or MATLAB, but allows the software engineer more control over aspects such as memory management.

Quick Links

-

MATLAB

-

Python

-

C++

-

API 2.4 (.zip)

-

Examples (GitHub)

-

Issue Tracker (Github)

-

Python Package (PyPI)

-

API Examples (GitHub)

-

API 3.16.0 (.zip)

-

API 3.16.0 (.tar.gz; preserves symlinks for macOS/Linux shared libraries)

-

API Documentation (Doxygen)

-

Examples (GitHub)

Also available are earlier versions of the API and Doxygen documentation.

The examples are divided into a few folders: basic, advanced, and kits. The basic examples are designed as a hands-on tutorial for getting started with the API; we highly recommend downloading and going through these examples as concrete/runnable examples of the concepts discussed in this documentation.

|

Installation/Project Integration

-

MATLAB

-

Python

-

C++

| The HEBI API for MATLAB requires MATLAB R2013b or newer. |

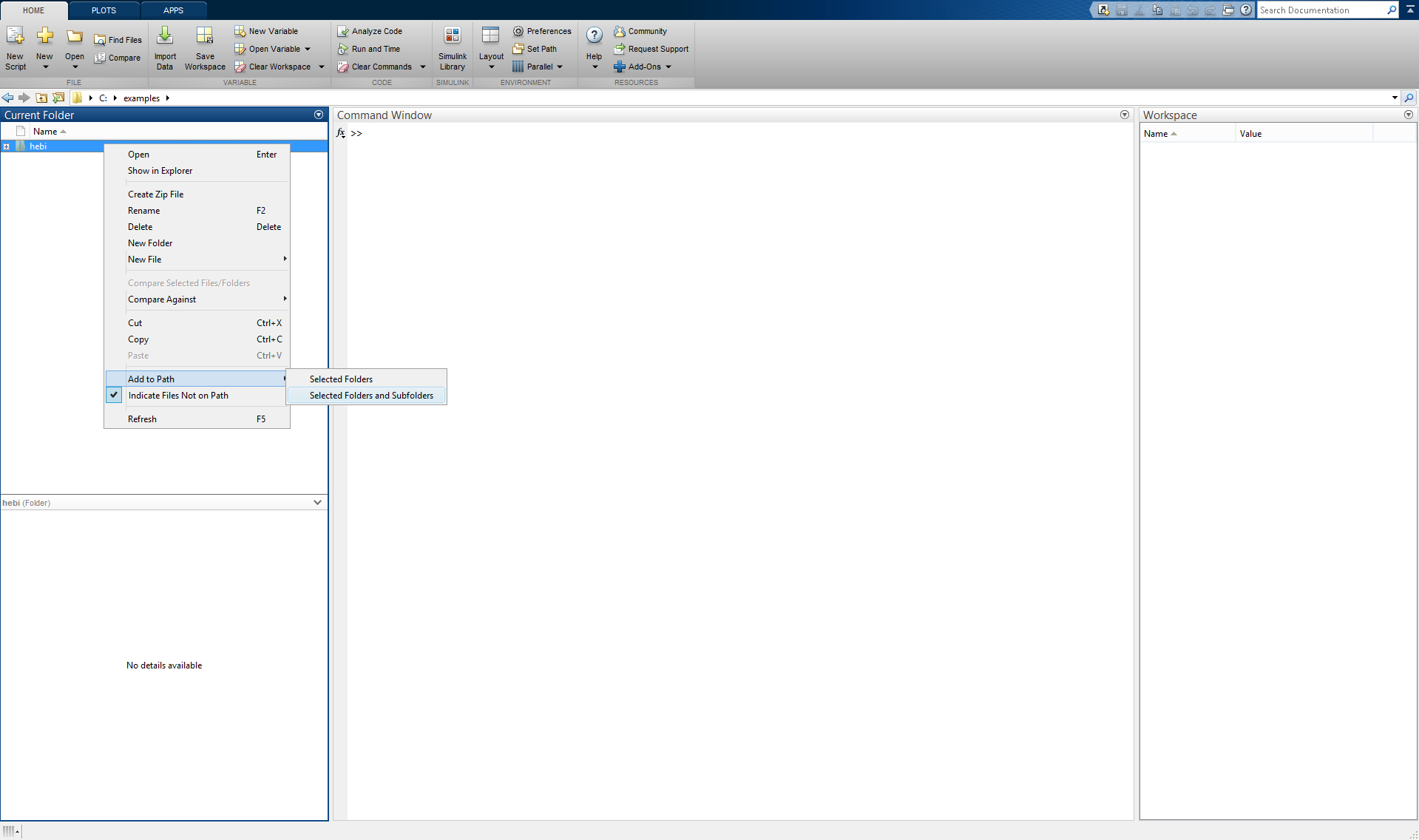

First, download the latest Release and extract the contents into a directory of your choice. Then, open MATLAB and add the "hebi" directory to the search path.

The path can be added manually by right-clicking on the directory,

or programmatically by calling the built-in addpath function.

addpath([pwd '/hebi']);For incorporating the HEBI library into a project, we recommend creating a startup script that can add the necessary files automatically.

function [] = startup()

% startup sets up libraries and should be started once on startup.

currentDir = fileparts(mfilename('fullpath'));

addpath(fullfile(currentDir , 'hebi'));

hebi_load(); % explicitely pre-load library

end

It is usually a good idea to increase MATLAB’s Java Heap Size using the slider control panel in Preferences→General→Java Heap Memory. In particular this will allow larger .hebilog files to be loaded into memory.

|

NOTE: As of hebi-py version 2.0.0, only Python 3 is supported. You must use a hebi-py version 1.x.y

for Python 2 compatibility.

The HEBI Python API is available through PyPI, which requires the use of pip.

The API requires numpy, which is available on practically any platform Python 3 is supported.

For some functions in the hebi.util module, matplotlib is required; however,

matplotlib is not a hard requirement since it may not be available on machines without a graphical user interface (e.g., a Linux machine without an X server).

It is recommended to install matplotlib through your package managers on most Linux distros.

Matplotlib’s website documentation elaborates more on specific dependencies and how to compile from source.

|

While not a requirement for the HEBI Python API itself, some of the kit examples (e.g., igor) also require some SDL libraries:

The GitHub examples repository provides the SDL2 library for Windows users.

It is automatically loaded when necessary on Windows, but not for Linux and

MacOS. Linux and MacOS users must install it themselves. Debian/Ubuntu

users can install it using sudo apt-get install libsdl2-2.0-0 and Fedora/RHEL

users can install it using sudo [yum|dnf] install SDL2.

|

Installing from the command line

From the command line, you can download the API from pip:

# On Linux, it is recommended to install to the user directory

pip install --user hebi-py

# Other platforms (e.g., Windows, MacOS)

pip install hebi-pyInstalling from IDEs

Most modern IDEs (e.g., PyCharm) have pip integration by default.

You can use the provided facilities to find the hebi-py package and install it.

Remarks

Some Linux distributions prefer you to install numpy through their package manager.

For example, Ubuntu uses the package python3-numpy; Red Hat/CentOS/Fedora use python3-numpy.

For some Linux environments, you may not be able to easily install matplotlib because

you do not have a desktop environment (e.g., running a server Linux install on a Raspberry Pi).

For such environments, you cannot use the plotting functions under hebi.util, but the rest

of the API will not be affected.

The C++ API is made up of:

-

The

.cppand.hppfiles that comprise the source code of the C++ wrapper around the underlying C library. -

The

hebi.hheader file that provides the function declarations for the underlying C library. -

The actual dynamic/shared object library that must be linked into your program (

.dllfor Windows,.sofor Linux, and.dylibfor macOS).

| The C++ API is designed to be used with the C++ 11 standard; when building your project, ensure you have set the proper compiler switches to enable this support (e.g., -std=c++11 for gcc). |

There are a few basic ways to integrate the API into your program:

-

If you are using Visual Studio, use the NuGet package manager to add the HEBI C++ API as a dependency. You will have to disable "precompiled header" support for the API to properly compile with your project.

-

Use the examples as a template for setting up a CMake or Visual Studio project dependent on the C++ API.

-

Add the source

.cppfiles to your project sources, ensure your include path contains the.hppandhebi.hfile, and link in the shared object for your platform and architecture.

Device Discovery

The HEBI APIs provide an easy to use facility to discover and communicate with HEBI modules on network interfaces. The HEBI Lookup class encapsulates a background process that automatically discovers HEBI devices on the local network using UDP broadcast messages.

The default settings of the Lookup object should be appropriate for most users, but are configurable.

-

MATLAB

-

Python

-

C++

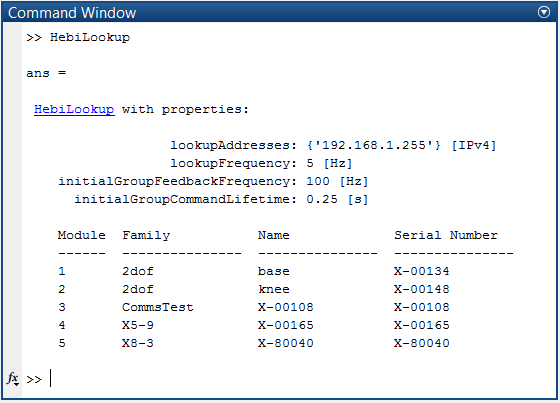

The first call to HebiLookup initializes the background discovery process

HebiLookupThe default settings may be changed in hebi_config.m.

This Lookup class acts as a singleton, but can be disposed of after creating the desired Group objects.

import hebi

lookup = hebi.Lookup()Generally, you will only need one hebi::Lookup object per application, and it can be disposed of after creating the desired hebi::Group objects (see Device Selection).

#include "lookup.hpp"

int main() {

// Create Lookup

hebi::Lookup lookup;

// Do stuff...

return 0;

}The default settings may be changed by calling functions on the hebi::Lookup object.

Displaying the Lookup object provides an overview of all devices that are visible on the network. The Family and Name fields/columns show the user-settable names.

-

MATLAB

-

Python

-

C++

Here the Serial Number field/column shows the unique serial number of each device as well.

% explicit display

disp(HebiLookup);

% implicit display (no semicolon)

HebiLookup

To view the modules that have been discovered, use the EntryList class to programmatically access the contents at a snapshot in time.

The entries also have fields such as IP address and MAC address, and whether or not the module is "stale" (no longer responding to requests from the Lookup object).

import hebi

from time import sleep

lookup = hebi.Lookup()

# Give the Lookup process 2 seconds to populate entries

sleep(2)

print('Modules found on network:')

for entry in lookup.entrylist:

print(f'{entry.family} | {entry.name}')Depending on the available modules, the output will look similar to

Modules found on network:

Arm | J1_base

Arm | J2_shoulder

Arm | J2_elbow

Base | left_wheel

Base | right_wheelTo view the modules that the Lookup has discovered, use the hebi::LookupEntry class to programmatically access the contents at a snapshot in time.

The entries also have fields such as IP address and MAC address, and whether or not the module is "stale" (no longer responding to requests from the Lookup object).

// Create Lookup and wait for it to populate

hebi::Lookup lookup;

std::this_thread::sleep_for(std::chrono::seconds(2));

// Take snapshot and print to the screen

auto entry_list = lookup.getEntryList();

std::cout << "Modules found on network:" << std::endl;

for (auto entry : entry_list)

{

std::cout << entry.family_ << " | " << entry.name_ << std::endl;

}Depending on the available modules, the output will look similar to:

Modules found on network:

Arm | J1_base

Arm | J2_shoulder

Arm | J2_elbow

Base | left_wheel

Base | right_wheelIn case you need programmatic access to other details (e.g. ip address, mechanical type, etc.) of all devices, you can use the group interface.

-

MATLAB

-

Python

-

C++

% form a group of all devices

devices = HebiLookup.newGroupFromFamily('*');

infoTable = devices.getInfo();lookup = hebi.Lookup()

# form a group of all devices

devices = lookup.get_group_from_family('*')

info = devices.request_info()Some fields (such as Ethernet Info, Firmware Version Info, UserData, Runtime Data, aren’t included by default to reduce network traffic, and can be requested with the request_info_extra function:

// retrieve info

info = devices.request_info_extra()hebi::Lookup lookup;

std::this_thread::sleep_for(std::chrono::seconds(2));

// form a group of all devices

auto group = lookup.getGroupFromFamily("*");

// retrieve info

GroupInfo group_info(group->size());

bool success = group->requestInfo(&group_info);Some fields aren’t included by default due to their size, and can be requested with the requestInfoExtra hebi::Group function:

// retrieve info

bool success = group->requestInfoExtra(&group_info, InfoExtraFields::EthernetInfo | InfoExtraFields::FirmwareInfo);(see the enum documentation for the InfoExtraFields linked from the requestInfoExtra function. Note that you can bitwise-or these enums to retrieve multiple, such As

static_cast<InfoExtraFields>(InfoExtraFields::EthernetInfo | InfoExtraFields::FirmwareInfo))

Note the info request can fail (throw an error in MATLAB, return None in Python, and return false in C++) if devices are 'stale' (haven’t responded in several seconds) in which case stale devices would have to be cleared first:

-

MATLAB

-

Python

-

C++

% reset everything to the initial state

HebiLookup.initialize()

% rebuild only the device table

HebiLookup.clearModuleList();

pause(0.5); % allow time to re-buildlookup.reset()lookup.reset()If for some reason devices are not listed, please refer to the following troubleshooting table.

| Problem | Suggestions |

|---|---|

A device fails to get an IP address (LED fades orange / green) |

|

A device did successfully get an IP address (e.g. LED fades green), but is not visible in the lookup |

|

The lookup does not initialize to the default settings (MATLAB) |

|

If you encounter an issue connecting to devices that was not covered in the table above, please contact us directly.

Joint-Level Control

Device Selection

The Lookup object can create a Group instance. A group is a collection of modules (often part of the same robotic system), and the group interface represents the basic way to send commands and retrieve feedback. They provide convenient ways to deal with modules and handle high-level issues such as data synchronization and logging. Modules can be identified by user settable parameters, such as name or family, or hardware constants, such as their serial number or mac address.

-

MATLAB

-

Python

-

C++

A HebiGroup can be created from HebiLookup in different ways:

% Creating a group by selecting custom names

family = 'leg';

names = {'hip', 'knee'};

group = HebiLookup.newGroupFromNames(family, names);% Can provide a different family for each module

families = {'mobile_base', 'mobile_base', 'arm', 'arm'};

names = {'left_wheel', 'right_wheel', 'shoulder', 'elbow'};

group = HebiLookup.newGroupFromNames(families, names);% Creating a group by selecting constant serial numbers

serials = {

'X-00134'

'X-00148' };

group = HebiLookup.newGroupFromSerialNumbers(serials);% Providing '*' as the family selects all modules

devices = HebiLookup.newGroupFromFamily('*');A comprehensive list of all available calls for selecting devices can be found in the HebiLookup API.

A Group can be created from HebiLookup in different ways:

# Create a group from a set of names

group = lookup.get_group_from_names(['leg'], ['hip', 'knee'])# Can provide a different family for each module

families = ['mobile_base', 'mobile_base', 'arm', 'arm']

names = ['left_wheel', 'right_wheel', 'shoulder', 'elbow']

group = lookup.get_group_from_names(families, names)# Providing '*' as the family selects all modules

group = lookup.get_group_from_family('*')The Lookup class documentation provides a comprehensive set of functions used to create group objects.

A hebi::Group can be created from HebiLookup in different ways:

// Create a group from a set of names

std::shared_ptr<Group> group = lookup.getGroupFromNames({"leg"}, {"hip", "knee"});// Can provide a different family for each module

std::vector<std::string> families = {"mobile_base", "mobile_base", "arm", "arm"};

std::vector<std::string> names = {"left_wheel", "right_wheel", "shoulder", "elbow"};

std::shared_ptr<Group> group = lookup.getGroupFromNames(families, names);// providing "*" as the family selects all modules

std::shared_ptr<Group> group = lookup.getGroupFromFamily("*");The Lookup class documentation provides a comprehensive set of functions used to create group objects.

| The example names and serial numbers need to be modified to match devices that were found on your network during the discovery step. |

| If you do not have access to physical devices, you can still test the API or control algorithms using the Imitation Device feature in Scope. |

Commands

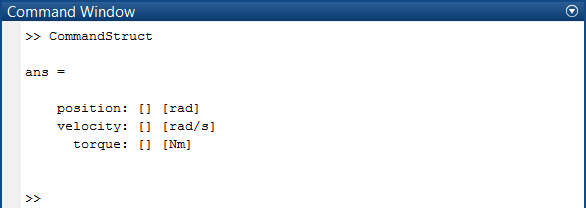

Position, velocity, torque (effort), and many other fields can be commanded by using the Command API functions. A CommandStruct (MATLAB) or GroupCommand object (Python/C++) are used to store the commands to be sent to the group.

-

MATLAB

-

Python

-

C++

Position, velocity, and torque (effort) can be commanded by using a CommandStruct.

Each field expects a 1xN vector where N is the number of devices within a group. Leaving a field empty or setting a value within a vector to NaN corresponds to turning the corresponding control loop off.

% Send a zero force/effort command to a group with two actuators

cmd = CommandStruct();

cmd.effort = [0 0];

group.send(cmd); % immediately sends messages to all grouped devicesA GroupCommand object

is used to store the commands to be sent to the group with the group.send_command() function.

We use types from the numpy library

to update many of the fields with vectors of data.

# numpy is aliased to np throughout this documentation.

import numpy as np

import hebi

# Create a numpy array filled with zeros

efforts = np.zeros(group.size)

# Command all modules in a group with this zero force or effort command

group_command = hebi.GroupCommand(group.size)

group_command.effort = efforts

group.send_command(group_command)

The command affects the actuator control loops only if at least one of the position, velocity, and effort command fields is not cleared.

In particular, a command sent with all three of these cleared will not affect the control loop setpoints.

However, if only a subset of the fields are set (e.g., only position), then commands from the other fields will be cancelled when this message is receieved.

If you want to completely cancel out a previous command (especially when the Command Lifetime is not set!) and turn the control loops off,

you can set the commanded value to nan.

|

A few ways to get a nan in Python are:

# parse from string

a = float('nan')

# numpy provides it as an attribute

b = np.nanThe individual Command elements of a

GroupCommand

object can also be

accessed and updated individually. Note that you cannot create an instance of

Command - you only retrieve references through a

GroupCommand.

The Command object provides the same interface as a GroupCommand, but with

all of the fields returning a scalar as opposed to a vector or matrix.

As an example, updating the name of the module in the following example:

import hebi

group_command = hebi.GroupCommand(group.size)

command = group_command[0] # Retrieve reference to the command for first module

command.name = "new name"

# Only changes the name for the first module

group.send_command_with_acknowledgement(group_command)A hebi::GroupCommand object is used to store the commands to be sent to the group. We use types from the open-source C++ matrix library Eigen to update many of the fields with vectors of data.

// Create an Eigen vector object filled with zeros

Eigen::VectorXd efforts(group->size());

efforts->setZero();

// Command all modules in a group with this zero force or effort command

hebi::GroupCommand group_command(group->size());

group_command.setEffort(efforts);

group->sendCommand(group_command);

The command affects the actuator control loops only if at least one of the position, velocity, and effort command fields is not cleared.

In particular, a command sent with all three of these cleared will not affect the control loop setpoints.

However, if only a subset of the fields are set (e.g., only position), then commands from the other fields will be cancelled when this message is receieved.

If you want to completely cancel out a previous command (especially when the Command Lifetime is not set!) and turn the control loops off,

you can set the commanded value to NAN (see std::numeric_limits::quiet_NaN).

|

The individual hebi::Command elements of a GroupCommand object can also be accessed and updated individually. Note that you cannot create an instance of Command - you only retrieve references through a GroupCommand. The hebi::Command object provides a hierarchical message that provides access to all of the available options that can be sent through the API — for example, updating the name of the module in the following example:

hebi::GroupCommand group_command(group->size());

hebi::Command& command = group_command[0]; // retrieve reference to command for first module

command.settings().name().set("new name");

bool success = group->sendCommandWithAcknowledgement(group_command);The Command class documentation provides complete documentation of the Command class fields.

Setting the values in the CommandStruct/GroupCommand object does not affect/command any modules until the command is sent to the group.

|

| Individual commands only set the low-level controller targets for the current instant in time, and do not calculate a trajectory from the current state to the desired target state. In other words, setting a single position command will result in a step response from the actuator. If you’d like a smooth motion between two or more positions, please take a look at the Trajectory API. |

Command Lifetime

Commands are only valid for a limited command lifetime, so even unchanging setpoints need to be re-sent before they expire. This means that is a script or process is killed (e.g., with ctrl-c), commanded motions are aborted. By default, the command lifetime is 250ms.

-

MATLAB

-

Python

-

C++

This is set on a per-group basic via the CommandLifeTime function.

% Set command lifetime to 100ms

group.setCommandLifetime(0.1);

% Self commands in a loop to continue

cmd = CommandStruct();

while true

cmd.position = [0 0];

group.send(cmd); % immediately sends messages to all grouped devices

pause(0.01);

endThis is set on a per-group basis with the Group.command_lifetime field.

# Sets command timeout to 100 milliseconds

group.command_lifetime = 100.0

# Command must be sent in loop at a faster rate than the lifetime in order to remain in effect.

while not stop_loop:

group.send_command(group_command)

sleep(0.01)This is set on a per-group basis with the hebi::Group::setCommandLifetimeMs() function.

Note that this function will return 'false' if

attempting to set a value longer than the maximum allowable command lifetime.

// Sets command timeout to 100 milliseconds

group->setCommandLifetimeMs(100);

// Command must be sent in loop at a faster rate than the lifetime in order to remain in effect.

while (!stop_loop)

{

group->sendCommand(group_command);

std::this_thread::sleep_for(std::chrono::milliseconds(10));

}Example Use Cases

The following example shows an open-loop controller commanding sine waves with different frequencies on two actuators using simultaneous position and velocity control.

-

MATLAB

-

Python

-

C++

% Two actuators executing sine waves of 1Hz and 2Hz

group = HebiLookup.newGroupFromNames('leg', {'knee', 'ankle'});

cmd = CommandStruct();

w = 2 * pi * [1 2];

t0 = tic();

while true

t = toc(t0);

cmd.position = sin( w * t );

cmd.velocity = cos( w * t ) * w;

group.send(cmd);

pause(0.001);

end% Two actuators executing sine waves of 1Hz and 2Hz

group = lookup.get_group_from_names(["leg"], ["knee", "ankle"])

group.command_lifetime = 20.0

group_command = hebi.GroupCommand(group.size)

w = np.array([math.pi*2.0, math.pi*4.0], dtype=np.float64)

w_t = np.empty(2, dtype=np.float64)

t = 0.0

dt = 0.01 # 10 ms

while not stop_loop:

np.multiply(w, t, w_t)

group_command.position = np.cos(w_t)

group_command.velocity = np.sin(w_t)

group.send_command(group_command)

sleep(dt)

t = t + dt#include <cmath> // provides M_PI

...

// Two actuators executing sine waves of 1Hz and 2Hz

auto group = lookup.getGroupFromNames({"knee", "ankle"}, {"leg"});

group->setCommandLifetimeMs(20);

hebi::GroupCommand group_command(group->size());

Eigen::VectorXd w

<< 2.0 * M_PI,

4.0 * M_PI;

// It is good practice not to allocate this every loop iteration.

Eigen::VectorXd w_t(2);

double t = 0.0;

double dt = 0.01; // 10 ms

while (!stop_loop) {

w_t = w * t;

group_command.setPosition(w_t.array().cos());

group_command.setVelocity(w_t.array().sin());

group->sendCommand(group_command);

std::this_thread::sleep_for(std::chrono::milliseconds(dt * 1000.0));

t += dt;

}Note in addition to actuator commands such as position, velocity, and effort, we can also command values for other types of modules. Here, we set the value on an I/O board digital output pin to 'high'.

-

MATLAB

-

Python

-

C++

The IoCommandStruct serves as a similar structure to command the outputs on an I/O board. Note that for I/O boards we found it to be more maintainable to create a mapping and to access the individual pin fields by string as shown below.

% Pin mapping

led_r = 'c6';

% Turn on red LED

group = HebiLookup.newGroupFromNames('IO_BOARD', 'sensor interface');

cmd = IoCommandStruct();

cmd.(led_r) = 1;

group.send(cmd);group = lookup.get_group_from_names(["IO_BOARD"], ["sensor interface"])

group_command = hebi.GroupCommand(group.size)

group_command.io.c.set_int(6, 1) # set IO pin "c6" to 1 for every module in group

group.send_command(group_command)auto group = lookup.getGroupFromNames({"IO_BOARD"}, {"sensor interface"});

hebi::GroupCommand group_command(group->size());

group_command[0].io().c().setInt(6, 1); // Set IO pin "c6" to 1 for the first module in the group

group->sendCommand(group_command);Delivery Acknowledgement

Commands can be dropped on particularly poor or congested networks, and the Group "send" functions do not provide guaranteed delivery or even an acknowledgement of receipt; they are designed for relatively high-frequency applications where commands are resent frequently (e.g. 100Hz).

For commands that are only sent once (such as setting gains on the modules), we recommend using the send command with acknowledgement functions to provide positive confirmation that the command was received.

-

MATLAB

-

Python

-

C++

When sending a command, adding 'RequestAck' requests message acknowledgements from each

device, and will return true if acknowledgements have been received from all devices

within this group and within the specified timeout.

send

success = group.send(cmd, 'RequestAck', true);(also, see the HebiUtils.sendWithRetry example in the Gains section below)

See the Group.send_command_with_acknowledgement function.

success = group.send_command_with_acknowledgement(group_command)Use Group::sendCommandWithAcknowledgement to verify the command was received.

success = group->sendCommandWithAcknowledgement(group_command);Other Commands

The Group API "send" methods additionally supports various other commands such as programmatically setting names, resetting devices, setting safety limits, and setting LED colors. LEDs can for example be used to provide live feedback to people standing next to a robot, or for synchronizing/debugging motions in combination with a high-speed camera.

-

MATLAB

-

Python

-

C++

LEDs and other commands can be sent with the send method.

group.send('led', 'red'); % set all to red

group.send('led', [0 0 1]); % set all to blue [r g b] [0-1]

group.send('led', []); % reset to default modeYou can override the LED color on each individual module.

# Set all to red

color = hebi.Color(255, 0, 0) // red, green, blue

group_command = GroupCommand(group.size)

group_command.led.color = color

# This is equivalent:

# group_command.led.color = 'red'

group.send_command(group_command)-

and allow the module to reclaim control over the color.

# Set all to be module controlled

# This is the default mode

group_command = GroupCommand(group.size)

group_command.led.color = 'transparent'

group.send_command(group_command)You can override the LED color on each individual module.

// Set all to red

hebi::Color color(255, 0, 0); // red, green, blue

hebi::GroupCommand groupCommand(group->size());

for (int i = 0; i < group->size(); i++) {

groupCommand[i].led().setOverrideColor(color);

}

group->sendCommand(groupCommand);-

and allow the module to reclaim control over the color.

// Set all to be module controlled

// This is the default mode

hebi::GroupCommand groupCommand(group->size());

for (int i = 0; i < group->size(); i++) {

groupCommand[i].led().setModuleControl();

}

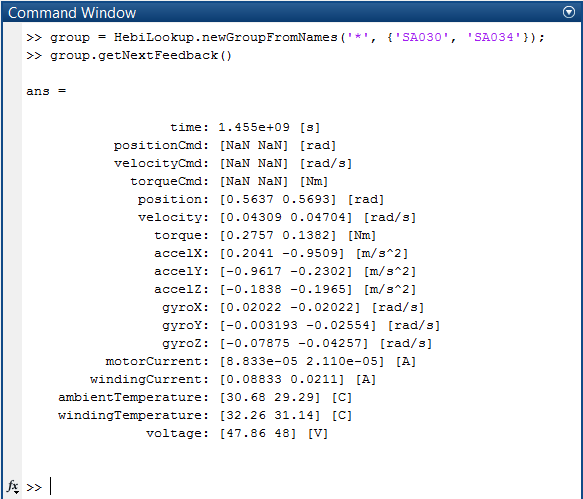

group->sendCommand(groupCommand);Feedback

Each group continuously gathers sensor feedback from all contained devices in a background thread, and synchronizes the data into a single struct. This loop rate of this background thread is the Group’s feedback_frequency, which defaults to 100Hz and is configurable on a per-group basis. A group can asynchronously access the received feedback with the "get next feedback" function. Note that each call returns the next new (not previously accessed) synchronized feedback. Thus, a single feedback response will never be returned more than once. If there is no new feedback since the last call to this function, it will block and wait for a new packet (up to a configurable timeout), so this can be used as an easy way to control the rate of a loop. For example:

-

MATLAB

-

Python

-

C++

Call getNextFeedback to return the next feedback, and to change the default rate call setFeedbackFrequency or modify the hebi_config.m file.

% This effectively sets the rate of the loop below to (a maximum of) 200Hz

group.setFeedbackFrequency(200.0)

while running

fbk = group.getNextFeedback()

endOur devices tend to return a large number of sensors, so we have added different 'views' in order to enable advanced use cases without confusing new users. The default view returns feedback of the most used types of sensors, but there are alternative views in case you’d like to access additional information such as hardware timestamp data.

% Basic feedback (position, velocity, effort (e.g. torque), IMU data, temperature)

fbk = group.getNextFeedback();

% Advanced feedback including hardware timestamps

fbk = group.getNextFeedbackFull();

% I/O board feedback

ioFbk = group.getNextFeedbackIO();

% Mobile device feedback including location services and AR features

mobileFbk = group.getNextFeedbackMobile();Call Group.get_next_feedback to return the next feedback, and set Group.feedback_frequency to change the default rate. Feedback is returned as a GroupFeedback object.

# Best practice is to allocate this once, not every loop iteration

group_feedback = hebi.GroupFeedback(group.size)

# This effectively sets the rate of the loop below to (a maximum of) 200Hz

group.feedback_frequency = 200.0

while not stop_loop:

if group.get_next_feedback(reuse_fbk=group_feedback) is None:

continue

# ... read/use feedback object contents here.The GroupFeedback object contains position, velocity, and effort actuator feedback, as well as sensor feedback from a number of sensors. Similar to commands, many of the values can be accessed as numpy vectors or matrices, with one row for each module in the group.

# Fill in feedback

group_feedback = hebi.GroupFeedback(group.size)

group_feedback = group.get_next_feedback(reuse_fbk=group_feedback)

# Retrieve positions:

positions = group_feedback.position

print(f'Position Feedback:\n{positions}')

# Get Gyro

gyros = group_feedback.gyro

print(f'Gyro Feedback:\n{gyros}')

# Individually access io pin feedback from first module

io_a = group_feedback.io.a

if (io_a.has(1)):

print(f'PinA: {io_a.get_int(1)[0]}')Call getNextFeedback() on the Group to return the next feedback, and call Group::setFeedbackFrequencyHz to change the default rate.

Feedback is returned as a Group Feedback object.

// Best practice is to allocate this once, not every loop iteration

hebi::GroupFeedback feedback(group->size());

// This effectively sets the rate of the loop below to (a maximum of) 200Hz

group->setFeedbackFrequencyHz(200);

while (!stop_loop)

{

if (!group->getNextFeedback(&feedback))

continue;

// ... read/use feedback object contents here.

}The GroupFeedback object contains position, velocity, and effort actuator feedback, as well as sensor feedback from a number of sensors. Similar to commands, many of the values can be accessed as Eigen vectors or matrices, with one row for each module in the group. Fields can also be accessed via individual hebi::Feedback object references, which allow hierarchical access to all information contained in the feedback message.

// Fill in feedback

hebi::GroupFeedback group_feedback(group->size());

group->getNextFeedback(&group_feedback);

// Retrieve positions:

Eigen::VectorXd positions = group_feedback.getPosition();

std::cout << "Position feedback: " << std::endl << positions << std::endl;

// Update an existing Eigen vector or matrix (eliminates a copy operation)

Eigen::MatrixX3d gyros(group->size());

group_feedback.getGyro(gyros);

std::cout << "Gyro feedback: " << std::endl << gyros << std::endl;

// Individually access io pin feedback from first module

auto& io_a = group_feedback[0].io().a();

if (io_a.has(1))

std::cout << "Pin A1: " << io_a.get(1) << std::endl;| The actual feedback frequency is fundamentally limited by the underlying operating system’s scheduler. For example, code that executes at a rate of 1KHz in Linux may be limited to ~640Hz on Windows 7. For typical rates below 250Hz this tends to be irrelevant. The Importance of Metrics and Operating Systems contains more information about the expected performance for various operating systems. |

| Feedback from multiple devices is typically synchronized to within 1ms. However, the actual timings depends on the network layout and external network traffic. Please see Analyzing the viability of Ethernet and UDP for robot control for more information. |

Other Methods to Return Feedback

In Python and C++, there are two other approaches to return feedback from a group that may be appropriate for some use cases. The first is a callback-based approach, where the background thread that is synchronizing feedback from individual modules invokes the callback each time a new synchronized GroupFeedback is available. To use this method, use the API to add a feedback handler with the designated function signature:

-

MATLAB

-

Python

-

C++

The callback-based approach is not compatible with the MATLAB API.

# Function feedback callback

def feedback_func_callback(feedback):

# feedback is guaranteed to be a "hebi.GroupFeedback" instance

# ... read/use feedback object contents here

# Sets frequency to 200 Hz

group.feedback_frequency = 200.0

# Add feedback handler

group.add_feedback_handler(feedback_func_callback)The C++ 11 std::function will automatically convert function pointers and lambda functions to a function object. The callback will execute on a background thread. Below we show two methods for adding a callback function

// Function feedback callback

static void feedback_func_callback(const hebi::GroupFeedback& const feedback) {

// ... read/use feedback object contents here

}

void foo() {

// Sets frequency to 200 Hz

group->setFeedbackFrequencyHz(200);

// Method 1: Add pointer to function

group->addFeedbackHandler(feedback_func_callback);

// Method 2: Add a lambda function; see C++ reference for more info

group->addFeedbackHandler(

[](const hebi::GroupFeedback& const feedback) -> void {

// ... read/use feedback object contents here

}

);

}The second method allows finer grained control over the network traffic that is sent. You can retrieve feedback when the feedback frequency is zero by manually sending a feedback request.

-

MATLAB

-

Python

-

C++

The "send individual request" approach is not compatible with the MATLAB API.

group_feedback = hebi.GroupFeedback(group.size)

# Sends a request to the modules for feedback and immediately returns

group.send_feedback_request()

# Blocks until feedback is in the background queue or timeout

group_feedback = group.get_next_feedback(reuse_fbk=group_feedback)hebi::GroupFeedback feedback(group->size());

// Sends a request to the modules for feedback and immediately returns

group->sendFeedbackRequest();

// Blocks until feedback is in the background queue or timeout

group->getNextFeedback(&feedback);

Setting the feedback frequency on the group effectively calls the send feedback request function at a certain rate on a background thread.

|

Closed-Loop Control Example

The below example shows a closed-loop controller that implements a virtual spring that controls torque (effort) to drive the output towards the origin (stiffness = 1 Nm / rad).

-

MATLAB

-

Python

-

C++

% Virtual spring on single device

group = HebiLookup.newGroupFromNames('HEBI', 'J1');

cmd = CommandStruct();

stiffness = 1; % [Nm/rad]

while true

fbk = group.getNextFeedback();

cmd.effort = -stiffness * fbk.position;

group.send(cmd);

endimport hebi

# Virtual spring

lookup = hebi.Lookup()

# change to your name(s)/family(s)

group = lookup.get_group_from_names(["HEBI"], ["J1"])

command = hebi.GroupCommand(group.size)

stiffness = 1.0 # [Nm/rad]

feedback = hebi.GroupFeedback(group.size)

while not stop_loop:

# wait for the feedback

if group.get_next_feedback(reuse_fbk=feedback) is None:

continue

command.effort = feedback.position * -stiffness

group.send_command(command)Using a lambda callback, this can be rewritten as:

import hebi

# Virtual spring

lookup = hebi.Lookup()

# change to your name(s)/family(s)

group = lookup.get_group_from_names(["HEBI"], ["J1"])

command = hebi.GroupCommand(group.size)

stiffness = 1.0 # [Nm/rad]

def fbk_handler(feedback):

command.effort = feedback.position * -stiffness

group.send_command(command)

group.add_feedback_handler(fbk_handler)// Virtual spring

hebi::Lookup lookup;

auto group = lookup.getGroupFromNames({"HEBI"}, {"J1"}); // change to your name(s)/family(s)

hebi::GroupCommand command(group->size());

hebi::GroupFeedback feedback(group->size());

const double stiffness = 1.0; // [Nm/rad]

while (!stop_loop) {

if (!group->getNextFeedback(&feedback)) // wait for the feedback

continue;

command.setEffort(-stiffness * feedback.getPosition());

group->sendCommand(command);

}Using a lambda callback, this can be rewritten as:

// Virtual spring

hebi::Lookup lookup;

auto group = lookup.getGroupFromNames({"HEBI"}, {"J1"}); // change to your name(s)/family(s)

hebi::GroupCommand command(group->size());